Swiss Rock Force

Pebble Pounder

As you had in an early video a wet course, how do you think your electrics expossed with no heat shrink etc will go? From memory you have a slightly snowey enviroment

you are right. this is still a bit risky.

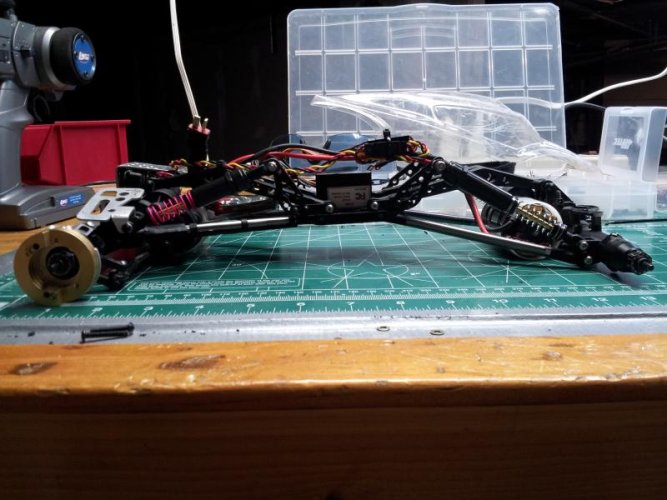

here is my solution:

https://www.distrelec.ch/ishopWebFr...CH_01_968653&gclid=COGd3pSxs7YCFcdX3godEgkAnA

this saves the electronics from water almost without increasing the weight. it also does not isolate heat for the esc's.