Steven McKay

Quarry Creeper

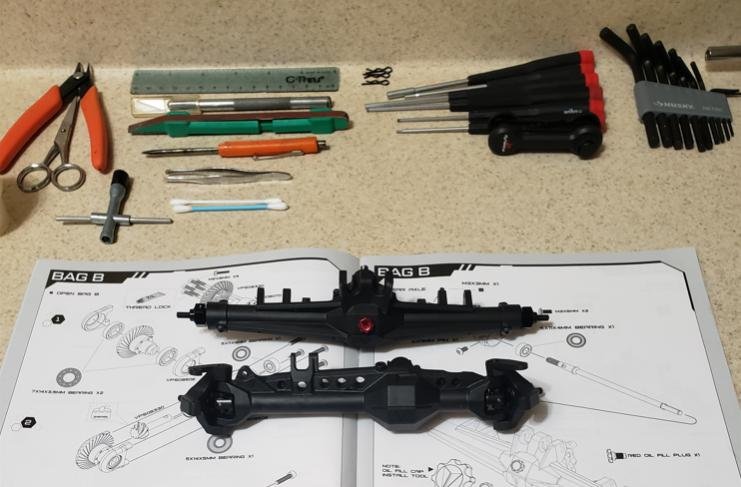

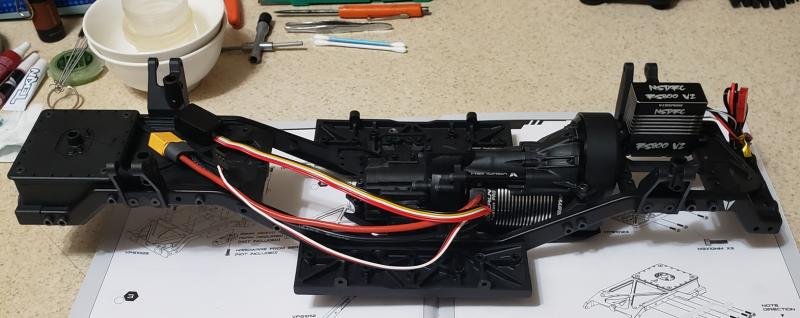

Originally I was going to use this kit and part it out for my flatbed. But have decided to build it. I will build my flatbed at a later date. I started my axles and when I started the rear axle I wondered why I had just 3 5x11x4mm bearings when the instructions show 5. I wondered why the axles where out so far and saw the pin hole out so far with the end caps on. I preceded to install the bearings the way the opposing page showed and of course it all came together.