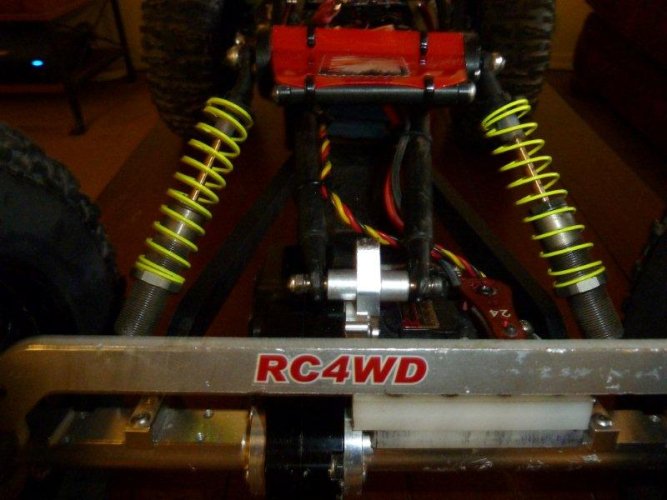

CREEPERBOB

Yashua

Looking good Robert! Sounds like your getting comfortable with the rig.

Thanks Michael, yeah it's getting a little more comfortable to drive, all of the buttons are feeling better now "thumbsup". I love this rig :mrgreen:.

I ordered a couple sets of cvd pin's from Gunner , i'll be removing the axle shafts this week to check out and if nessecery I'll replace the pin's and or axles themselves if I've worked them too hard.Will also be a great time to check all the bearings too.

Last edited: