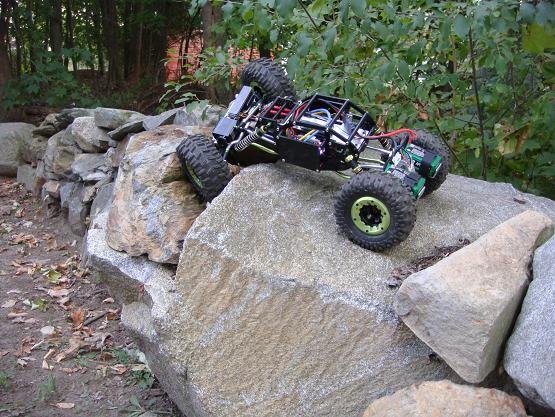

no rush on the short nose replacement parts. i'm looking forward to getting them but i'm planning on having a blast with this thing on the rocks. sweet chassis! you came up with a winner in my opinion!

this is my first crawler and i'm loving it. i missed the time years ago when i could just tweak and tune an rc car. but i'm definitely addicted now. the wish list is growing: brushless motor, aluminum wheels, new tires, new servo and bec, 4/5 channel 3-position module (i have a tq2.4 4 channel radio and want the 3 position dig versus 2 position i'm running now; somebody in the electronics forum is putting together something)... all i need now is a second income!

oh yeah, and some lights. the days are getting pretty short!

this is my first crawler and i'm loving it. i missed the time years ago when i could just tweak and tune an rc car. but i'm definitely addicted now. the wish list is growing: brushless motor, aluminum wheels, new tires, new servo and bec, 4/5 channel 3-position module (i have a tq2.4 4 channel radio and want the 3 position dig versus 2 position i'm running now; somebody in the electronics forum is putting together something)... all i need now is a second income!

oh yeah, and some lights. the days are getting pretty short!