Nabil

no talent hack

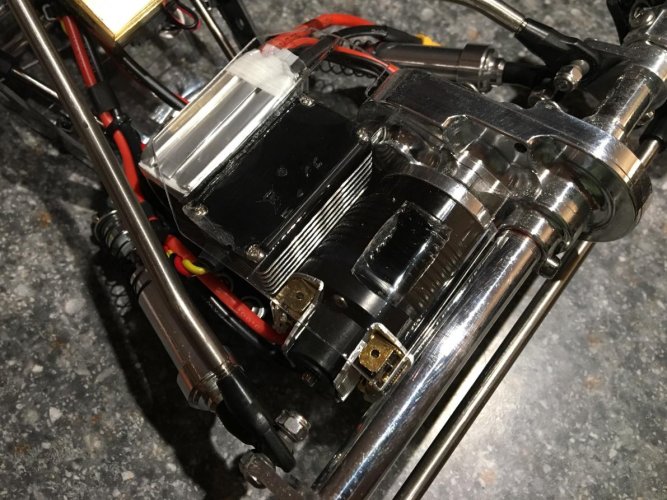

Yeah you are right, they don’t compress all the way. I run a 3mm spacer between the cup and rod end. Also make sure the rodend is fully screwed on. It should go past the threads a little bit. You could always machine a spacer the same diameter as the spring cup and not have to worry about the little disc. Or use a countersunk washer flipped over...

Last edited: