-

Welcome to RCCrawler Forums.

It looks like you're enjoying RCCrawler's Forums but haven't created an account yet. Why not take a minute to register for your own free account now? As a member you get free access to all of our forums and posts plus the ability to post your own messages, communicate directly with other members, and much more. Register now!

Already a member? Login at the top of this page to stop seeing this message.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do to your TRX-4 today?

- Thread starter Miatardo

- Start date

Benp

Rock Crawler

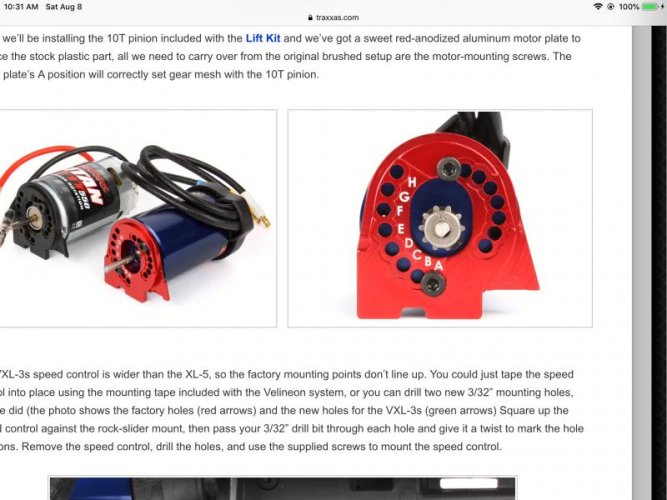

Would like to see a HH motor with 4 holes beside this photo with circles around which holes to use. Then this photo with a 9T pinion.

I got the Traxxas labeled 9T. I saw other brands but this looked the best machined and shape. There is a little noise from the truck but I do not know if it is the HH motor or the pinion. The motor I got on eBay did not have the new sticker for advancement. I moved it back and forth listening where the most power was..then backed off a little so reverse would have decent power. The HH motor had 4 holes. I picked two stacked on top of each other. Tried 9T with the 45T slot and did not match the motor hole. Would like to see an install video from someone doing just that with clear closeups. I found two that seemed to work. Placed the spur gear with the Allen facing the motor. Made sure the Allen did not touch the spur gear. Mesh looked good but I could not get a good look with the way it is bolted in. This rig is a beast now. Stops 3/4 up a rock and just sits there. Slow crawl is like slow motion. It crawls so slow that the default motor noise on my sound box does not know the motor is running till 3/8 throttle sometimes....need to recalibrate.

Tried the 70/30 with the stock transmitter. Reverse was not coming back to neutral...had to bump it. Went back to 50/50. I like the instant control. It still has enough range for me to do amazing slow crawls.

Will most likely do a 60/40 with the DX5 Rugged.

I will use HH website for the next purchase.

I checked the foam I make inners from...much denser than stock. How goes the foam battle BenP ?

My HH Revolver has 4 holes. I did it the same way as the other 2 that have 6. Pick one hole based on how you want the motor positioned on the mount. Put fastener into the lower corresponding mount letter per the chart. Tighten a bit. Physically Rotate the motor around until a motor hole lines up with the other upper corresponding mount hole. Put other fastener in and tighten. That’s all I’ve done for all 3.

To double check the mesh after getting the pinion depth correct, I put a piece of paper between pinion/spur and then securely mount just the motor.

The paper pulled out easy as spur and pinion rotated. Not too tight at all. I’d then loosen up the motor mount and drop the spur cover into position. I then tightened both pieces at the same time.

I was glad traxxas had the chart because I was brand new to this. Thank goodness for YouTube or I’d of been really lost.

I hope all that made sense.

I have a picture of current motor mounted in aluminum mount with 9t pinion. But I’m sure it’s 6 holes as well like my other motor. I’m pretty sure that’s a Robinson pinion in the pic.

As far as tuning your motor, that link I pasted a couple back goes over how to adjust the timing in depth. From using an amp meter to putting it on a kitchen table. I read it again last night and highly recommend checking it out.

Sounds like the it’s working out for you! That’s great! I love how slow it is.

Massive difference in drag brake between stock motor and esc to an upgrade.

Stock on an incline I’d just roll if I stopped.

Did you put the 4mm bullets on your new esc and motor?

I’m curious if there’s will be a big difference between the stock controller and the dx5. You’d “think” the dx5 would be better.

The tire foams......

I’m just letting things be the way they are for the moment. Haven’t done anything with them since new 4.7” foams went in last week. Sounds like a good project for winter. [emoji1787] I just takes me too long

Thursday I received a printed raised mamba x mount. I can run wiring underneath it to clean things up some and has mount for on/off switch. Today is a good day to mess with that.

Probably play with the desert lizard shocks again as well. I got another complete set of springs for them so I can mess with the preload more.

Last edited:

Benp

Rock Crawler

1 more thing.

If you’re looking at getting an aluminum motor mount don’t get the 1 piece one like traxxas one.

Get the 2 piece mount like this.

Much much more solid mount. My friend got the aluminum traxxas one and said the motor is still wobbly like stock. Maybe a slight improvement.

I got the 2 piece GRC mount and it’s rock solid.

Something to keep in mind.

If you’re looking at getting an aluminum motor mount don’t get the 1 piece one like traxxas one.

Get the 2 piece mount like this.

Much much more solid mount. My friend got the aluminum traxxas one and said the motor is still wobbly like stock. Maybe a slight improvement.

I got the 2 piece GRC mount and it’s rock solid.

Something to keep in mind.

Jeff6x6

Pebble Pounder

Thank you for the pic. Just after placing my post...I found an English accent man on You Tube installing a 9T on the TRX-4. The chart made sense as he ecplained both go on A positions. I was trying to keep the stock C position for the 45 spur and add the A position for the 9T..I was not understanding the chart correctly...All cleared up. I was able to swap out the stock TRX -4 pinion on my other stock TRX-4 as well. Wow..what a difference. I really do not see a need to touch this one anymore. Crawls great and has enough spunk to jump off of or on to a rock with the 3S.

I always like to improve items I have for my needs but the stock TRX-4 does so well with just a few modifications.

I soldered the leads to the HH motor. My local hobby shop had the Traxxas leads for my 1080 ESC test on stock motor. I wanted to see how each item worked on it’s own before I installed everything.

The Pitbull Rock Beasts are going In a box. They spin too much. The modified Canyons have the rig doing slow controlled wheelies On the rocks...so much traction. They are always clean looking after a session where the Rock Beasts have dirt clung to them.

I always like to improve items I have for my needs but the stock TRX-4 does so well with just a few modifications.

I soldered the leads to the HH motor. My local hobby shop had the Traxxas leads for my 1080 ESC test on stock motor. I wanted to see how each item worked on it’s own before I installed everything.

The Pitbull Rock Beasts are going In a box. They spin too much. The modified Canyons have the rig doing slow controlled wheelies On the rocks...so much traction. They are always clean looking after a session where the Rock Beasts have dirt clung to them.

Last edited:

Benp

Rock Crawler

Good deal[emoji106][emoji106]

That makes sense now as to the issues.

I believe I watched the same video. “Driftomatics “ I think?

Like I said thank goodness for YouTube.

The bump from the 3s makes up for loss of wheel speed by gearing down so much.

Awesome everything is coming together for you.

That makes sense now as to the issues.

I believe I watched the same video. “Driftomatics “ I think?

Like I said thank goodness for YouTube.

The bump from the 3s makes up for loss of wheel speed by gearing down so much.

Awesome everything is coming together for you.

Uncle Pete

Rock Stacker

1 more thing.

If you’re looking at getting an aluminum motor mount don’t get the 1 piece one like traxxas one.

Get the 2 piece mount like this.

Much much more solid mount. My friend got the aluminum traxxas one and said the motor is still wobbly like stock. Maybe a slight improvement.

I got the 2 piece GRC mount and it’s rock solid.

Something to keep in mind.

Benp, do you have a link the two piece mount ?

Thanks, Uncle Pete

Benp

Rock Crawler

Benp, do you have a link the two piece mount ?

Thanks, Uncle Pete

Uncle Pete,

This is the same brand I have. I got it from Asia tees though not from eBay.

https://www.ebay.com/itm/273646680815

Unfortunately it’s not an inexpensive item. I remember paying 30 something for it.

That being said here’s a cheaper one made out of alloy. I don’t know if there’s a big difference

Between alloy and aluminum strength wise though.

https://www.ebay.com/itm/392580825369

If you do a search for trx4 2 piece motor mount you might be able to find good prices.

It looks like they’ve come out with a 3 piece mount also that includes an aluminum bottom piece that the upper 2 attach to.

I definitely recommend the 2 piece one though.

You’ll be Be surprised how sturdy the motor will be compared to stock.

Jeff6x6

Pebble Pounder

All my TRX’s now have a 9T pinion. The 6x6 is a beast of a rig with the canyons modified. Blasted through my course without picking any lines. Will only take this out when my buddies and I cannot get up a certain rock that looks do-able.

Benp

Rock Crawler

That’s awesome!

Volt up/gear down!!!

Volt up/gear down!!!

Last edited:

Benp

Rock Crawler

Back to messing with the suspension trying to figure out a good droop setup with 110mm desert lizards.

Good droop but I had minimal preload/dampening.

Lots of tinkering ahead. Lol

A little tedious but I find it a better tedious than mounting tires. [emoji1787][emoji1787]

It’s raining today so I figured this is a great project.

Good droop but I had minimal preload/dampening.

Lots of tinkering ahead. Lol

A little tedious but I find it a better tedious than mounting tires. [emoji1787][emoji1787]

It’s raining today so I figured this is a great project.

vinnieb729

Rock Stacker

I've used one of the cheap CNC alloy ones and the GRC. No difference I could tell. Amazon has some of the CNC style in stock if you don't want to wait for shipping from overseas.Uncle Pete,

This is the same brand I have. I got it from Asia tees though not from eBay.

https://www.ebay.com/itm/273646680815

Unfortunately it’s not an inexpensive item. I remember paying 30 something for it.

That being said here’s a cheaper one made out of alloy. I don’t know if there’s a big difference

Between alloy and aluminum strength wise though.

https://www.ebay.com/itm/392580825369

https://www.amazon.com/dp/B081YHY796/ref=twister_B081YHYW78?_encoding=UTF8&psc=1

mr_alister

Quarry Creeper

You know, I've seen trucks running massive droop and no springs. I'm not exactly sure why you would do that. I've even seen trucks with the shocks installed upside down. People do all sorts of crazy things. Oh and pen spings inside the shock body too. I guess it depends what you're going for. No spings would be useless for a trail truck but maybe it's better for on the rocks? Seems to me that springs help push the tires down for traction.? So much to learn about this hobby!Back to messing with the suspension trying to figure out a good droop setup with 110mm desert lizards.

Good droop but I had minimal preload/dampening.

Lots of tinkering ahead. Lol

A little tedious but I find it a better tedious than mounting tires. [emoji1787][emoji1787]

It’s raining today so I figured this is a great project.

Benp

Rock Crawler

You know, I've seen trucks running massive droop and no springs. I'm not exactly sure why you would do that. I've even seen trucks with the shocks installed upside down. People do all sorts of crazy things. Oh and pen spings inside the shock body too. I guess it depends what you're going for. No spings would be useless for a trail truck but maybe it's better for on the rocks? Seems to me that springs help push the tires down for traction.? So much to learn about this hobby!

Oh I’m running springs.

My thought process is if a wheel is hanging in the air, the extra travel will allow it to get down a little to traction.

How accurate that will be remains to be seen. [emoji1787][emoji1787]. Like the majority of my thought process.

One side effect that I didn’t think of is driveline bind.

Sitting on the block with both fronts dangling, the bind is real bad.

I’m going to try running 10wt in the front and 15 in the back.

So we’ll see.

Worst case Ontario is back to the stock shocks that work just fine. [emoji106]

I've used one of the cheap CNC alloy ones and the GRC. No difference I could tell. Amazon has some of the CNC style in stock if you don't want to wait for shipping from overseas.

https://www.amazon.com/dp/B081YHY796/ref=twister_B081YHYW78?_encoding=UTF8&psc=1

Cool!!!! I ordered one. Thanks!!!

Last edited:

Uncle Pete

Rock Stacker

I've used one of the cheap CNC alloy ones and the GRC. No difference I could tell. Amazon has some of the CNC style in stock if you don't want to wait for shipping from overseas.

https://www.amazon.com/dp/B081YHY796/ref=twister_B081YHYW78?_encoding=UTF8&psc=1

Thanks.....just ordered one.

Benp

Rock Crawler

Got the shocks done.

It wound up pretty much being a full droop setup when the truck is on its wheels. Minimal up travel/dampening.

I stuck with soft springs and went with 2 medium length springs in each shock.

Due to the shock length it wound up raising the truck 1/8” at the center skid.

Sun showed up and things started drying out so I got to do a little testing. I trimmed up the front bumper so I threw that on also.

First thing I noticed was that in spots where the front tires were normally dangling a bit first, they dropped right down and contacted rocks.

So bigger drops/transitions were much more controlled.

Also seemed more stable going across the rocks by not dipping into holes as bad.

This one surprised me. Normally I’d drive the truck up to where the rear wheels contacted and then the truck would just spin and bounce a bit.

This time I actually went up a bit until the front lightened up too much. First time I’ve gone up.

This is another line where it’s a coin toss if I’d flop it at this spot. If the front drivers wheel hung in the air at all transitioning to the next rock, over she’d go.

Not this time. Tire dropped down onto the rock and went to the next one. I did this consistently.

Now moving to the left across the rocks in this spot, I’ve never been able to completely make the next rock.

Progressing, the rock gets narrower than the truck. The front outside wheel dropped down onto the side of the rock and kept going. Normally I’m rolling.

At the end with both wheels on the side of the rock it slide onto the drivers side some. If I cranked the wheels full passenger, the truck started to go uphill.

The circle is the spot I’m talking about. I was able to find a not good file photo so you get the idea.

At this point the neighbor asked if I could give him a hand in the shop annnnnnnnd it started pouring rain while in there.

Oh well. I got about 20 minutes of playing in.

I’m really pleased with the results of the shocks and am looking forward to more testing.

They are working the way I envisioned and noticed no real drawback to the lack of upward travel creeping on the rocks.

The bumper did good. The sound of scraping lexan was less prevalent than normal. [emoji1787][emoji1787]

It wound up pretty much being a full droop setup when the truck is on its wheels. Minimal up travel/dampening.

I stuck with soft springs and went with 2 medium length springs in each shock.

Due to the shock length it wound up raising the truck 1/8” at the center skid.

Sun showed up and things started drying out so I got to do a little testing. I trimmed up the front bumper so I threw that on also.

First thing I noticed was that in spots where the front tires were normally dangling a bit first, they dropped right down and contacted rocks.

So bigger drops/transitions were much more controlled.

Also seemed more stable going across the rocks by not dipping into holes as bad.

This one surprised me. Normally I’d drive the truck up to where the rear wheels contacted and then the truck would just spin and bounce a bit.

This time I actually went up a bit until the front lightened up too much. First time I’ve gone up.

This is another line where it’s a coin toss if I’d flop it at this spot. If the front drivers wheel hung in the air at all transitioning to the next rock, over she’d go.

Not this time. Tire dropped down onto the rock and went to the next one. I did this consistently.

Now moving to the left across the rocks in this spot, I’ve never been able to completely make the next rock.

Progressing, the rock gets narrower than the truck. The front outside wheel dropped down onto the side of the rock and kept going. Normally I’m rolling.

At the end with both wheels on the side of the rock it slide onto the drivers side some. If I cranked the wheels full passenger, the truck started to go uphill.

The circle is the spot I’m talking about. I was able to find a not good file photo so you get the idea.

At this point the neighbor asked if I could give him a hand in the shop annnnnnnnd it started pouring rain while in there.

Oh well. I got about 20 minutes of playing in.

I’m really pleased with the results of the shocks and am looking forward to more testing.

They are working the way I envisioned and noticed no real drawback to the lack of upward travel creeping on the rocks.

The bumper did good. The sound of scraping lexan was less prevalent than normal. [emoji1787][emoji1787]

Last edited:

mr_alister

Quarry Creeper

@Benp

Did you mount the desert lizards in the same hole as your stock ones? Or a lower hole for even more droop? Was the binding on the driveshafs an issue?

Over all it sounds like a pretty solid improvement!

Also, scraping lexan is like nails on a chalk board to me. Bumper looks good [emoji41] You dont run one on the rear at all right? At least, not until your vanquish ones arrive?

Did you mount the desert lizards in the same hole as your stock ones? Or a lower hole for even more droop? Was the binding on the driveshafs an issue?

Over all it sounds like a pretty solid improvement!

Also, scraping lexan is like nails on a chalk board to me. Bumper looks good [emoji41] You dont run one on the rear at all right? At least, not until your vanquish ones arrive?

Benp

Rock Crawler

@Benp

Did you mount the desert lizards in the same hole as your stock ones? Or a lower hole for even more droop? Was the binding on the driveshafs an issue?

Over all it sounds like a pretty solid improvement!

Also, scraping lexan is like nails on a chalk board to me. Bumper looks good [emoji41] You dont run one on the rear at all right? At least, not until your vanquish ones arrive?

The fronts are in the same position and the rears, I went up one hole so the ride height wouldn’t be increased.

There was no driveline binding that I was aware of. I was surprised because in that last truck

Picture the front driveshaft looks jacked. [emoji51]

Nope. No rear bumper currently. I’ll try the vanquish though.

Jeff6x6

Pebble Pounder

That’s good news. Don’t you love it when a plan comes together !

Benp

Rock Crawler

That’s good news. Don’t you love it when a plan comes together !

It was surprising to say the least.

Most of my plans don’t, no matter how perfect in my head they are. [emoji1787]

It was a little tedious but better than doing tires. Lol

I spent a long time messing with the front first to figure out the spring combo I wanted. As that one picture showed.

In the picture with the rig climbing you can see how much the front unloads.

I’m thinking of rigging a bungee from the rear to the front and attach it so it would keep the front sucked down during climbs.

Then for regular going, reattach it somehow so the front has full articulation.

More tinkering. Darn. [emoji23]

Speaking of articulation, the 3rd, panhard, and servo links are the fronts limiting factor regarding droop. They can only go so far.

I am absolutely fine with how it’s working now.

ETA- I’m thinking that bungee recovery strap that routes through the frame would work.

Then add something on to one of the front body posts to attach it to so the front stays down.

It’s a cheap enough option plus I’d gain a recovery strap.

Don’t really have an interest in a winch. Although that would work on the fly.

Last edited:

Jeff6x6

Pebble Pounder

Sounds like an internal winch is in order

Similar threads

- Replies

- 6

- Views

- 2K

- Replies

- 31

- Views

- 6K