Cole82

I wanna be Dave

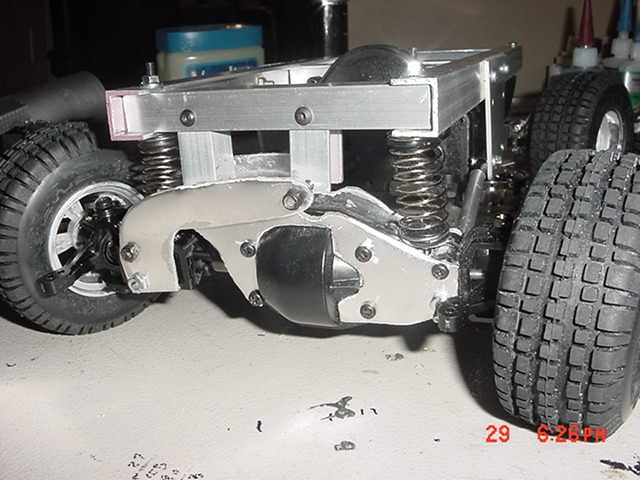

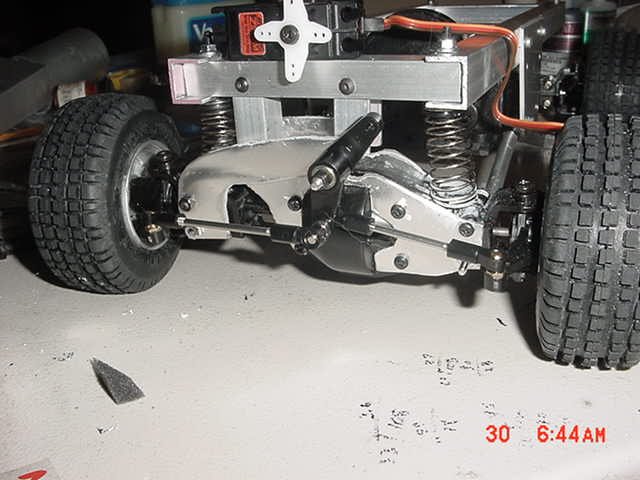

That's freakin sweet. Can you take a picture at full compression and fully extended.

The 8" is pretty close on the ranger four wheel drive and 2 wheel drive. The f150 had more because of the the longer arms.

The 8" is pretty close on the ranger four wheel drive and 2 wheel drive. The f150 had more because of the the longer arms.