The machine it replaced was not as easy to use. I went to great lengths to improve the low speed resolution and rigidity. Old machine had 1/4" shaft. This one has 1/2". Old machine would really pick up speed under load. This one doesn't really change RPM with the wire sizes typically formed into coils.

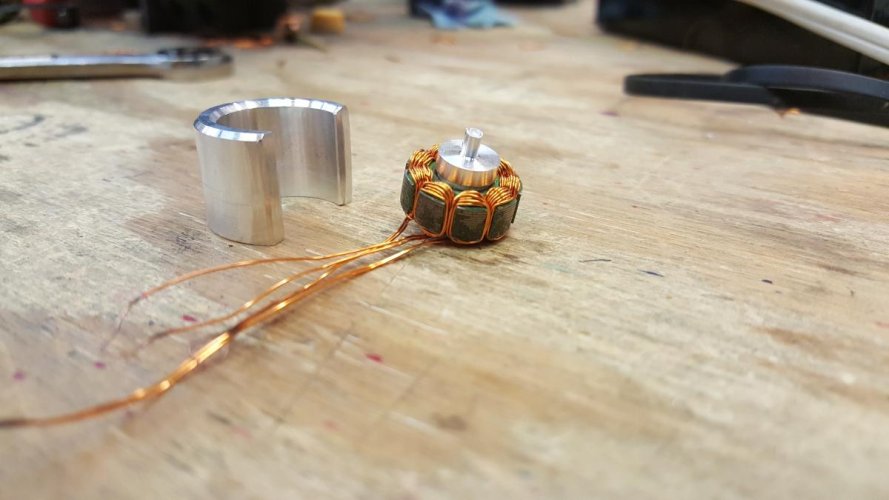

Motor is a modified ebike hub motor. Controller is a heavily modified ebike controller plus some additional peripheral components. I made a hall sensor pickup that works with the industrial counter. The last thing left is to hook up the reverse switch so it also reverses the counter, but it's not very often needed and low on my list.

Motor is a modified ebike hub motor. Controller is a heavily modified ebike controller plus some additional peripheral components. I made a hall sensor pickup that works with the industrial counter. The last thing left is to hook up the reverse switch so it also reverses the counter, but it's not very often needed and low on my list.