-

Welcome to RCCrawler Forums.

It looks like you're enjoying RCCrawler's Forums but haven't created an account yet. Why not take a minute to register for your own free account now? As a member you get free access to all of our forums and posts plus the ability to post your own messages, communicate directly with other members, and much more. Register now!

Already a member? Login at the top of this page to stop seeing this message.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Redcat steering thread

Wow, what a cool project Cabron. I love the way you won't need wheel wideners like every one else that is looking for more steering. Is that a home made chassis?

I see some potential here. You could cut it with a hack saw and then grind a flat spot for the set screw. Are those from D-lux? What was the cost for 2 short sides?

I thought you posted that you had a Berg too. What's the difference in length between a Berg short side and an Axial short side? My eyeball says that the Berg might even be too short, but I have never seen it in the flesh. Could you put one next to those other two by any chance?

Those universal couplers are the real score here. They open up a whole new world of options. Nice work on that.

I see some potential here. You could cut it with a hack saw and then grind a flat spot for the set screw. Are those from D-lux? What was the cost for 2 short sides?

I thought you posted that you had a Berg too. What's the difference in length between a Berg short side and an Axial short side? My eyeball says that the Berg might even be too short, but I have never seen it in the flesh. Could you put one next to those other two by any chance?

Those universal couplers are the real score here. They open up a whole new world of options. Nice work on that.

Last edited:

berg axles are a bit longer, not only that but the stock berg axles are dogbones.

I am using berg knuckles, almost a direct match to the rs10.

dlux makes axles for the berg by adding a tang at the end of the axial unis and doing

some grinding so the unis dont bind up. coupled with his knuckles you get a lot of steering

hence my estimate of 350 - 400 to do my berg with dual steering or an rs10 with dual steering.

if you want to get rid of those dlux knuckles let me borrow them for a bit. hahahaha

I just bought 8 of the berg high clearance knuckles from vanquish. the problem is that the axial

unis have a bit longer stub shaft as you found out. maybe the axial high clearance knuckles will work

but the berg ones were half price. hahahaha on me. i will have to make earrings out of the vanquish

knuckles

some guy was selling these short axles on ebay he had 3 of them at 8.00 each.

you can buy then for about 20 from dlux unmodified or ground for a bit more.

my idea with the uni couplers would be fine but I would have to use the dlux knuckles

to be able to adjust for the longer stub axle.

you can buy stock axial short and long axles for about 40 bucks a set. even the xr10 axles will work.

both will work when trimmed with the couplers I found.

these have one side 5mm the other side 4mm, they can be found with other

openings search ebay for couplers or I can try to find them for you. cheap 2 - 3 bucks

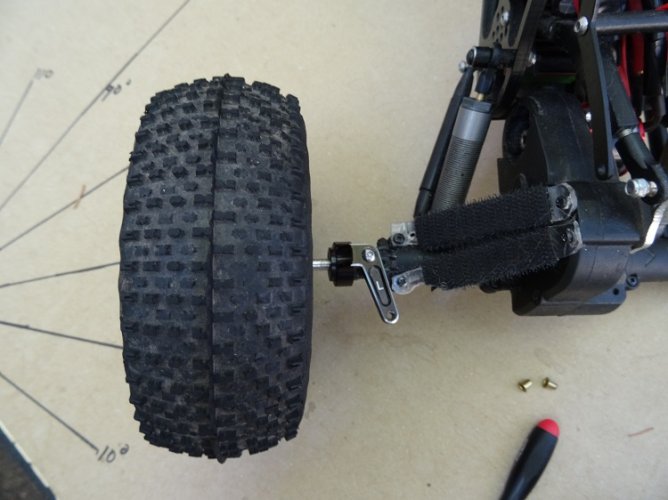

these are berg stock wheels and have a bit more offset than the rs10s so I don't need wideners.

I have other wheels with even more offset.

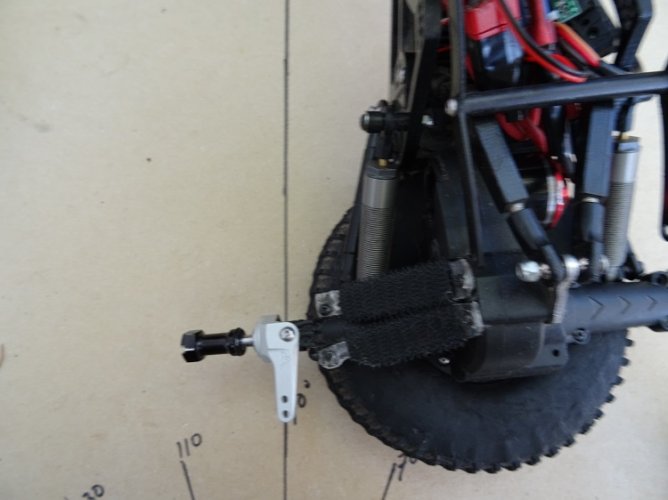

this is a type of stick chassis. I have pillow block bearings front and rear attached to the

housing which allow the whole housing to swing up or down as needed, my own design

I am using berg knuckles, almost a direct match to the rs10.

dlux makes axles for the berg by adding a tang at the end of the axial unis and doing

some grinding so the unis dont bind up. coupled with his knuckles you get a lot of steering

hence my estimate of 350 - 400 to do my berg with dual steering or an rs10 with dual steering.

if you want to get rid of those dlux knuckles let me borrow them for a bit. hahahaha

I just bought 8 of the berg high clearance knuckles from vanquish. the problem is that the axial

unis have a bit longer stub shaft as you found out. maybe the axial high clearance knuckles will work

but the berg ones were half price. hahahaha on me. i will have to make earrings out of the vanquish

knuckles

some guy was selling these short axles on ebay he had 3 of them at 8.00 each.

you can buy then for about 20 from dlux unmodified or ground for a bit more.

my idea with the uni couplers would be fine but I would have to use the dlux knuckles

to be able to adjust for the longer stub axle.

you can buy stock axial short and long axles for about 40 bucks a set. even the xr10 axles will work.

both will work when trimmed with the couplers I found.

these have one side 5mm the other side 4mm, they can be found with other

openings search ebay for couplers or I can try to find them for you. cheap 2 - 3 bucks

these are berg stock wheels and have a bit more offset than the rs10s so I don't need wideners.

I have other wheels with even more offset.

this is a type of stick chassis. I have pillow block bearings front and rear attached to the

housing which allow the whole housing to swing up or down as needed, my own design

Last edited:

Time for some nerding out with knuckles.

So here we have the Hot racing, Vanquish for Berg, and Vanquish for Axial. Notice how the Vanquish Axial Ax10/scx10 knuckle (The lighter colored one on the right) comes out straight and the other two have some angle to them. This is not a big deal because the Traxxas universals will bind up at 60 degrees, which is just before the knuckles would hit the axle due to the lean in they have. However, if you are having trouble with your particular configuration, it might be handy to see these angles to see which shape might help out the most.

Also notice that the black Vanquish for Bergs is a little longer than the other 2. (The vanquish Axial knuckle on the right is pushed forward a little bit, or this would be easier to see.) This could be handy for getting around the pumpkin with out having to bend your steering link, so keep it in mind if you are having an issue with hitting the pumpkin and not wanting to bend the rod.

So here we have the Hot racing, Vanquish for Berg, and Vanquish for Axial. Notice how the Vanquish Axial Ax10/scx10 knuckle (The lighter colored one on the right) comes out straight and the other two have some angle to them. This is not a big deal because the Traxxas universals will bind up at 60 degrees, which is just before the knuckles would hit the axle due to the lean in they have. However, if you are having trouble with your particular configuration, it might be handy to see these angles to see which shape might help out the most.

Also notice that the black Vanquish for Bergs is a little longer than the other 2. (The vanquish Axial knuckle on the right is pushed forward a little bit, or this would be easier to see.) This could be handy for getting around the pumpkin with out having to bend your steering link, so keep it in mind if you are having an issue with hitting the pumpkin and not wanting to bend the rod.

Attachments

Last edited:

Here we have the D-lux for Axial ax10/scx10, and the 2 bergs. Just showing the angles and lengths. You can see that the D-lux has a little lean in, but not much and this really shows how nice and straight the Vanquish axial is. It is also easier to see the added length on the Vanquish Berg on the right.

You can also see one of the 2 extra bearings that set the D-lux knuckle apart from any other knuckle I have seen so far. In terms of functionality, the Vanquish Axial in the center (That you can get for $35 and is my vote for best bang for the buck.), will do everything as good or better as the D-lux...except have that neato bearing. Plenty of people have done plenty of high level crawling with out that bearing, so ....just sayin.

You can also see one of the 2 extra bearings that set the D-lux knuckle apart from any other knuckle I have seen so far. In terms of functionality, the Vanquish Axial in the center (That you can get for $35 and is my vote for best bang for the buck.), will do everything as good or better as the D-lux...except have that neato bearing. Plenty of people have done plenty of high level crawling with out that bearing, so ....just sayin.

Attachments

Last edited:

Remember when I said that knuckles were the one place where stepping up, made the most difference in turning? Ehh....I stand corrected. All 4 of these knuckles go from 90 degrees to 30 degrees. Which is when the universal binds up. That guy that eyeballed it (a few posts back) and said it looked like 60 degrees....has a pretty good eye. Good job buddy.

Evidently I could have saved myself a lot of time, effort, and money, if I would have just stuck with that first hot racing knuckle I bought way back in the day. The first pic is the D-lux and the second one is hot racing. There might be a degree or two of difference, but that's about it.

Evidently I could have saved myself a lot of time, effort, and money, if I would have just stuck with that first hot racing knuckle I bought way back in the day. The first pic is the D-lux and the second one is hot racing. There might be a degree or two of difference, but that's about it.

Attachments

Last edited:

Here we can see what they all look like set up. You can see the extra length on the Vanquish berg, and you can see just how straight that Vanquish axial is. Obviously that one will bump into the battery mount a lot later than the other 2. Whatever hits the battery on this side, hits the servo mount on the other side. So it is an inherent limiting factor if you are going for ALL THE STEERING. In the real world, servo throw and universal binding will come into play before the angle of the knuckle arm does. If you did everything else up to it's theoretical maximum, the angle of the steering arm would eventually become an issue.

Attachments

Last edited:

That is a 15 mm wheel widener on there right now. With the Traxxas uni's 12 mm is probably fine. 60 degrees will not make the wheels hit the shocks at 15 mm (At least with this chassis), and it might just barely touch with a 12mm widener. With the 15 mm I am at 11 inches from outside edge to outside edge. The most width I tend to see on other crawlers is 10.75 inches in the front, so once again going to the 12 mm probably makes it just right width wise.

Last edited:

If I were advising a friend on how to get more steering on a Redcat type of budget I'd say this.

1) Get a $3 12 mm plastic Traxxas wheel widener.

2) Get the $35 Vanquish Axial Ax10 knuckle.

(I like the straightness and the holes for mounting weights later. There might be some of those Vanquish Bergs on close out for $21, but for $14 difference just do it right the first time.IMO)

3) Get the $12 Traxxas Slash stock universal joint/drive line.

4) Get 60 degrees of turning.

Instead of spending $50 for 60 degrees, you can always spend 3 - 4 times that and get another 10 degrees. I'm thinking that every degree beyond 60 will cost around $15 to $20 a degree (Based on what Cabron has said about the cost of the 70 degree set up) and 60 is really pretty darn good.

1) Get a $3 12 mm plastic Traxxas wheel widener.

2) Get the $35 Vanquish Axial Ax10 knuckle.

(I like the straightness and the holes for mounting weights later. There might be some of those Vanquish Bergs on close out for $21, but for $14 difference just do it right the first time.IMO)

3) Get the $12 Traxxas Slash stock universal joint/drive line.

4) Get 60 degrees of turning.

Instead of spending $50 for 60 degrees, you can always spend 3 - 4 times that and get another 10 degrees. I'm thinking that every degree beyond 60 will cost around $15 to $20 a degree (Based on what Cabron has said about the cost of the 70 degree set up) and 60 is really pretty darn good.

Last edited:

dlux takes apart the axial unis and grinds on the yokes to get the extra few degrees.

time is money

are you not using the inner knuckle bearing?

when I have that bearing in the knuckle the pivot pin will not line up with the knuckle bushing

using the axial unis. I don't remember what it was like using the slash unis. I was not

looking into the stub length.

by the way thanks for all the info and pictures.

it should help a lot of people trying to figure out what to do

time is money

are you not using the inner knuckle bearing?

when I have that bearing in the knuckle the pivot pin will not line up with the knuckle bushing

using the axial unis. I don't remember what it was like using the slash unis. I was not

looking into the stub length.

by the way thanks for all the info and pictures.

it should help a lot of people trying to figure out what to do

The only knuckle that I use 2 bearings on is the D-lux. All of the rest I don't use the inner bearing, but it does not cause any play or any other issues. It fits and seals real nice on them all.

Sounds like I need to take my uni apart and grind it up some then. Plastic and a dremmel should make it pretty easy work.

Sounds like I need to take my uni apart and grind it up some then. Plastic and a dremmel should make it pretty easy work.

if you do not want to use ebay here is one for tower hobby

TowerHobbies.com | RC4WD Mini 12mm Wheel Widener (4)

do you need more?????

or more retailers?

or send me the money and I will get them for you.

TowerHobbies.com | RC4WD Mini 12mm Wheel Widener (4)

do you need more?????

or more retailers?

or send me the money and I will get them for you.

Actually this is the wheel widener I was referring too.

New Traxxas Hex Wheel Hub 2 5x12mm Fr Rustler Stampede 2 3654 | eBay

$2.49 12mm is probably enough.

New Traxxas Hex Wheel Hub 2 5x12mm Fr Rustler Stampede 2 3654 | eBay

$2.49 12mm is probably enough.

Similar threads

- Replies

- 1

- Views

- 241

- Replies

- 120

- Views

- 6K

- Replies

- 13

- Views

- 871

- Replies

- 39

- Views

- 2K