LavaCapCrawling

Pebble Pounder

I saw the Trail Trekker on the shelf at the local hardware/hobby store and had to get it. I did not know the can I was opening. Purchased this thing like a month ago, been coming here for a bout six weeks. This forum has been super helpful, thanks.

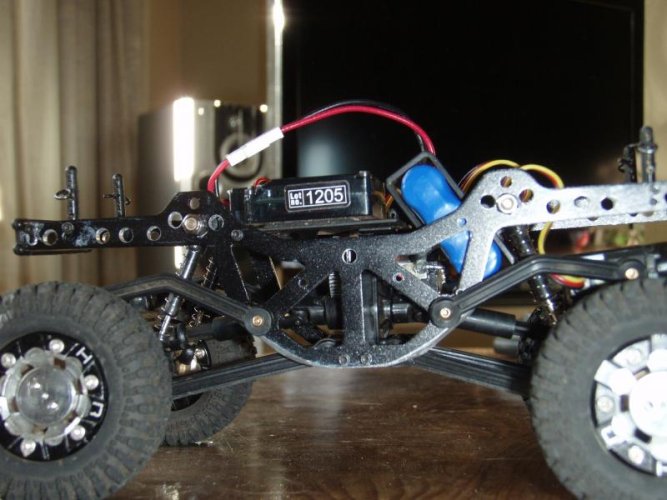

So far I have done the quick "Phase One" mods.

To the mods,

-Trimmed .187 from each spring.

-Removed factory limits.

-Hot Racing aluminum bead locks.(+11 grams per wheel)

-m2.5 steel lock nuts.

-Trimmed .125 off body all the way around.

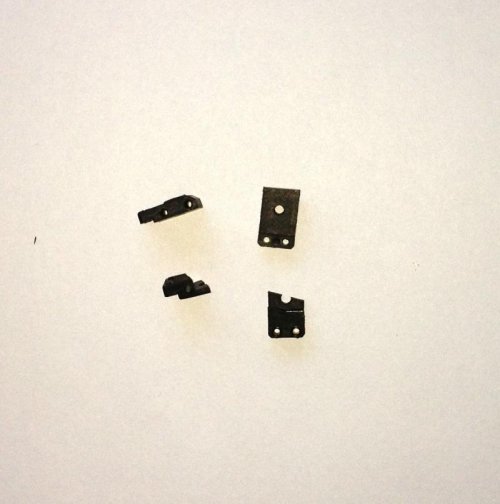

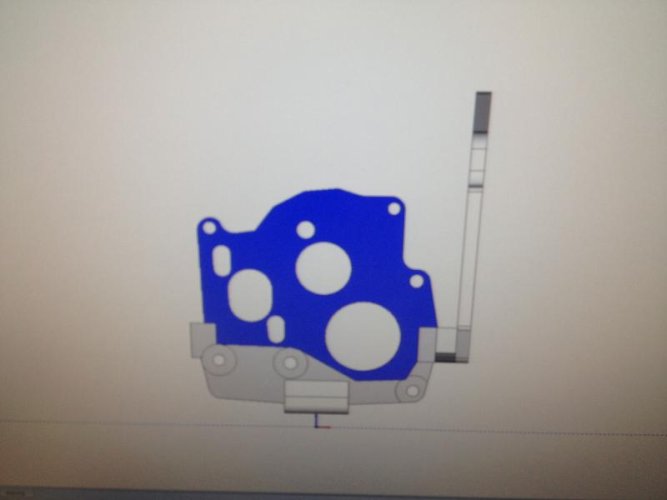

-Milled .021" off each servo mount to make room.

-Hitec 65mg, no saver.

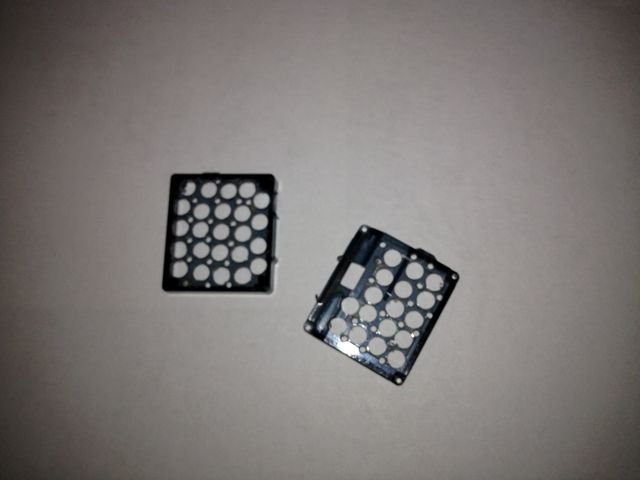

-Custom made weights/wideners(+9 grams)

Available at

http://www.rccrawler.com/forum/chas...new-product-trail-trekker-wheel-wideners.html

-experimenting with 5mm aluminum spacers on axle side of upper arms, seams to cause a soft bind or soft limit at full flex about .1 before shock limits and reduces torque twist. I remain undecided.

In the Mail,

-Roc Lox.

-HR 56t Spur.

-3pc brass pinion set.

All due to arrive Thursday.

So far I have done the quick "Phase One" mods.

To the mods,

-Trimmed .187 from each spring.

-Removed factory limits.

-Hot Racing aluminum bead locks.(+11 grams per wheel)

-m2.5 steel lock nuts.

-Trimmed .125 off body all the way around.

-Milled .021" off each servo mount to make room.

-Hitec 65mg, no saver.

-Custom made weights/wideners(+9 grams)

Available at

http://www.rccrawler.com/forum/chas...new-product-trail-trekker-wheel-wideners.html

-experimenting with 5mm aluminum spacers on axle side of upper arms, seams to cause a soft bind or soft limit at full flex about .1 before shock limits and reduces torque twist. I remain undecided.

In the Mail,

-Roc Lox.

-HR 56t Spur.

-3pc brass pinion set.

All due to arrive Thursday.

Attachments

Last edited: