jebster

I wanna be Dave

I have to thank MRCrackHead and Dlux for implanting the bug to build one of these myself. My wallet is not happy!  (And like others I'm not sure which board to post in so this will do for now.)

(And like others I'm not sure which board to post in so this will do for now.)

That being said I am looking to do this on a budget. I will probably never comp with it but I thought it would be a good fun rig to bring along to run 2.2p courses between runs.

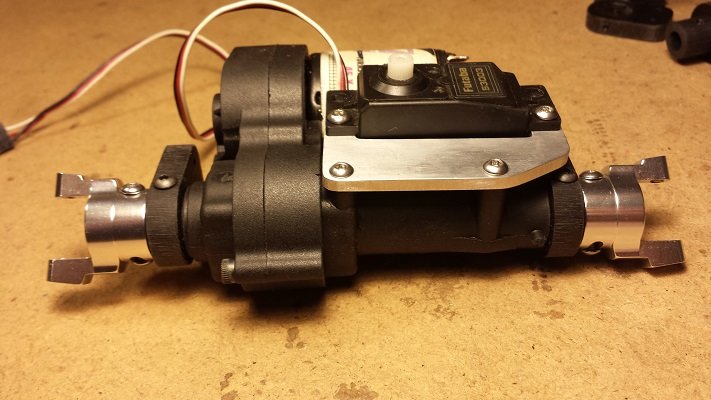

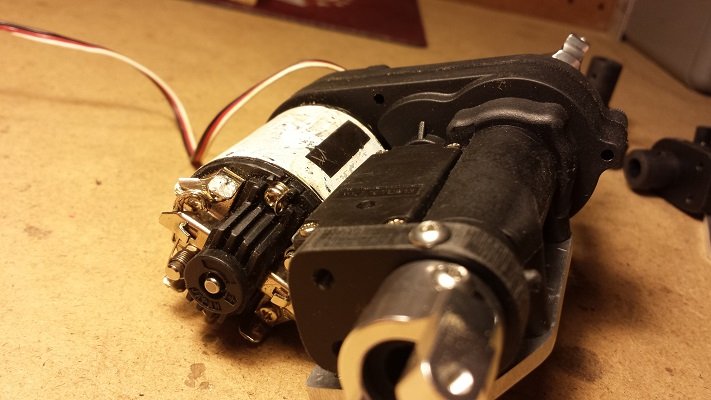

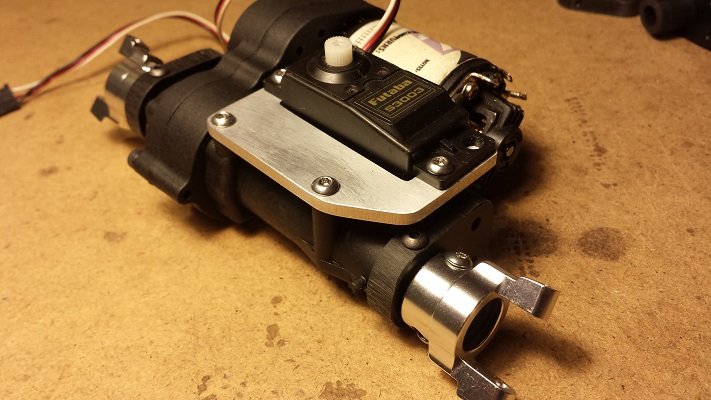

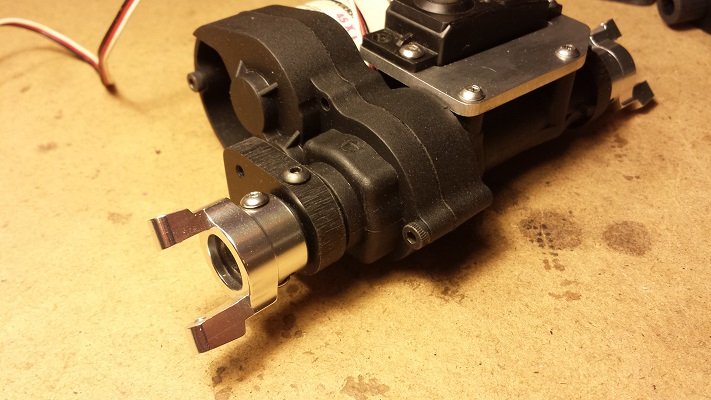

Following MRCrackHead's lead I decided to go with madtorque axles. I got the berg gear and RCBros locker combined with the plastic gears.

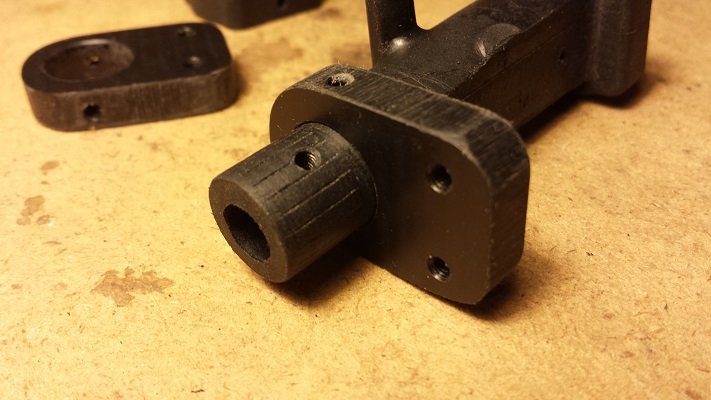

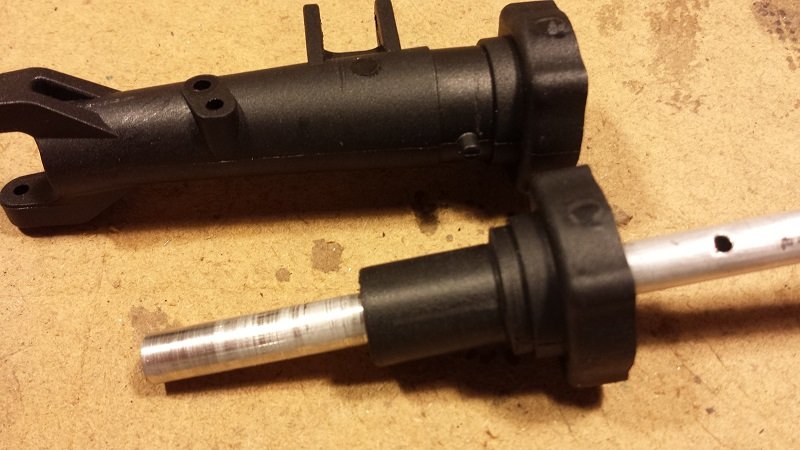

I cut down the axle tubes to the desired length then needed to figure out how to turn them down for vanquish c-hubs. I don't have a lathe but I do have a drillpress. So, I put a aluminum tube of the perfect diameter through the axle tubes and spun them on the drill press and used different files to get them to the correct diameter. I used a nylon block at in the vice to hold the bottom of the tube straight. It all worked out really nice. I left them a little big because I plan on press fitting the c-hubs on to cut some splines.

The one real problem I have is the gearbox is binding. It appears the 14t small gear is binding against the 40t gear. Not sure why this is an issue. I've tried a few adjustments but it isn't working. My next option is to get a 12t gear, cut the shaft down to the right length and use that instead. From the last picture below it looks like this would still provide plenty of gear engagement.

I have some pics of the progress so far. This may take awhile but I couldn't wait to get started.

That being said I am looking to do this on a budget. I will probably never comp with it but I thought it would be a good fun rig to bring along to run 2.2p courses between runs.

Following MRCrackHead's lead I decided to go with madtorque axles. I got the berg gear and RCBros locker combined with the plastic gears.

I cut down the axle tubes to the desired length then needed to figure out how to turn them down for vanquish c-hubs. I don't have a lathe but I do have a drillpress. So, I put a aluminum tube of the perfect diameter through the axle tubes and spun them on the drill press and used different files to get them to the correct diameter. I used a nylon block at in the vice to hold the bottom of the tube straight. It all worked out really nice. I left them a little big because I plan on press fitting the c-hubs on to cut some splines.

The one real problem I have is the gearbox is binding. It appears the 14t small gear is binding against the 40t gear. Not sure why this is an issue. I've tried a few adjustments but it isn't working. My next option is to get a 12t gear, cut the shaft down to the right length and use that instead. From the last picture below it looks like this would still provide plenty of gear engagement.

I have some pics of the progress so far. This may take awhile but I couldn't wait to get started.

Attachments

-

20150529_093831 v1.jpg126.5 KB · Views: 1,779

20150529_093831 v1.jpg126.5 KB · Views: 1,779 -

20150529_153327 v1.jpg148.3 KB · Views: 1,759

20150529_153327 v1.jpg148.3 KB · Views: 1,759 -

20150529_153314 v1.jpg143.5 KB · Views: 1,739

20150529_153314 v1.jpg143.5 KB · Views: 1,739 -

20150529_153705 v1.jpg146.1 KB · Views: 1,780

20150529_153705 v1.jpg146.1 KB · Views: 1,780 -

20150529_153218 v1.jpg132.4 KB · Views: 1,805

20150529_153218 v1.jpg132.4 KB · Views: 1,805 -

20150529_093813 v1.jpg140.2 KB · Views: 1,770

20150529_093813 v1.jpg140.2 KB · Views: 1,770 -

20150529_093729 v1.jpg123.6 KB · Views: 1,774

20150529_093729 v1.jpg123.6 KB · Views: 1,774