-

Welcome to RCCrawler Forums.

It looks like you're enjoying RCCrawler's Forums but haven't created an account yet. Why not take a minute to register for your own free account now? As a member you get free access to all of our forums and posts plus the ability to post your own messages, communicate directly with other members, and much more. Register now!

Already a member? Login at the top of this page to stop seeing this message.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Guido: Scale TTC Bronco 2015 Scale Nats Updates

- Thread starter Grizzly4x4

- Start date

Marq

Newbie

"thumbsup"

Oh I dig the hell out of Guido... But I have to say I miss The Duke.

Thanks Pinch, now I'm sad..... sigh

You guys are making me sad.Oh... Duke!

8)"thumbsup"

g23crawler

Rock Stacker

Got any updates on this thing man, i really want to se how your dual shock setup works. This is one amazing build great work "thumbsup"

Got any updates on this thing man, i really want to se how your dual shock setup works. This is one amazing build great work "thumbsup"

Thanks g23. 8) It just so happens that I do have some updates.

Friday after work I got to work on the rear links. I wanted a Carnage Crew/Trophy truck inspired link mounted shock system but I don't have time to scratch build square links. I thought about machining something but I wanted something different so here's what I came up with.

First I designed some dual shock mounts that I could weld to a set of round links.

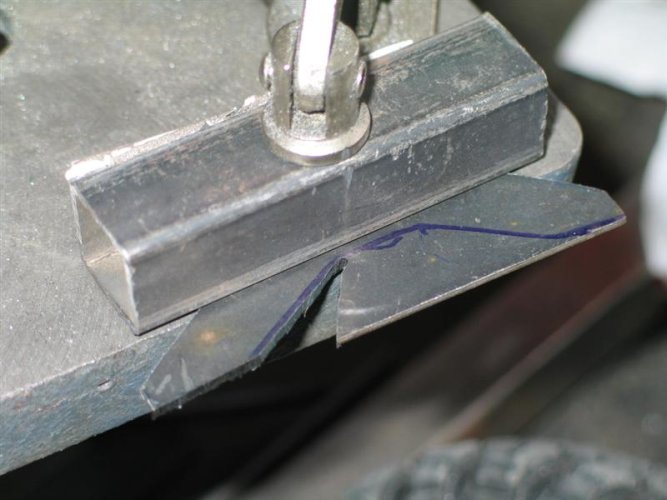

Next I cut some 1/4" brakeline and 10-24 all-thread to length for the links.

I cut a notch in the center of the tube and welded the tube to the all-thread so that they would be one piece and the tube could not spin on the all-thread.

I added some Revo rod ends and they were done. The blue Traxxas shock o-ring is to keep the link from flopping side to side. This works well with the Maxx rod ends but the o-ring is a bit too thin for the Revo rod ends so I'll have to go to the hardware store and find some thicker o-rings.

Attachments

Last edited:

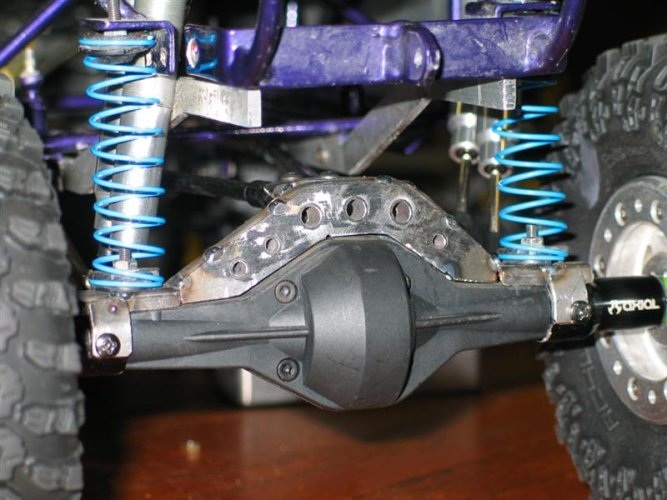

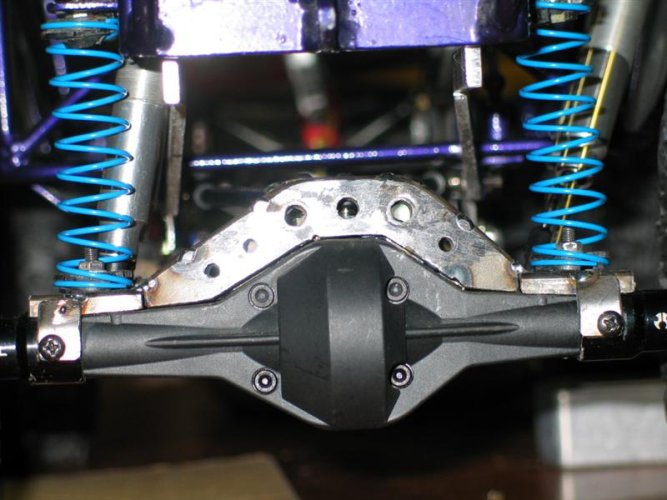

Next up was the truss. 1/2" square tube for the coil spring mounts, 3/16" rod for the truss backbone, and .060" plate for the filler. "thumbsup"

Attachments

-

20100315_ 020 (Medium).jpg65.7 KB · Views: 1,170

20100315_ 020 (Medium).jpg65.7 KB · Views: 1,170 -

20100315_ 019 (Medium).jpg66.5 KB · Views: 1,166

20100315_ 019 (Medium).jpg66.5 KB · Views: 1,166 -

20100315_ 025 (Medium).jpg70.5 KB · Views: 1,142

20100315_ 025 (Medium).jpg70.5 KB · Views: 1,142 -

20100315_ 026 (Medium).jpg75.9 KB · Views: 1,153

20100315_ 026 (Medium).jpg75.9 KB · Views: 1,153 -

20100315_ 024 (Medium).jpg85.1 KB · Views: 1,141

20100315_ 024 (Medium).jpg85.1 KB · Views: 1,141 -

20100315_ 023 (Medium).jpg84.7 KB · Views: 1,192

20100315_ 023 (Medium).jpg84.7 KB · Views: 1,192 -

20100315_ 022 (Medium).jpg64.8 KB · Views: 1,153

20100315_ 022 (Medium).jpg64.8 KB · Views: 1,153 -

20100315_ 021 (Medium).jpg57.4 KB · Views: 1,154

20100315_ 021 (Medium).jpg57.4 KB · Views: 1,154

Last edited:

I hadn't planned to spend an entire day on this truss because I wanted to make the chassis a roller by the end of the weekend. But, after getting the truss on there I decided that it looked ugly and was in need of some speed holes. So I drilled out some 1/4" and 3/16" holes and filled them with brakeline. I'm really stoked with how the truss turned out and the extra work was damn sure worth it I think.

Attachments

-

20100315_ 027 (Medium).jpg92.2 KB · Views: 1,144

20100315_ 027 (Medium).jpg92.2 KB · Views: 1,144 -

20100315_ 028 (Medium).jpg97.4 KB · Views: 1,145

20100315_ 028 (Medium).jpg97.4 KB · Views: 1,145 -

20100315_ 029 (Medium).jpg95.9 KB · Views: 1,133

20100315_ 029 (Medium).jpg95.9 KB · Views: 1,133 -

20100315_ 004 (Medium).jpg86.9 KB · Views: 1,128

20100315_ 004 (Medium).jpg86.9 KB · Views: 1,128 -

20100315_ 003 (Medium).jpg93.9 KB · Views: 1,136

20100315_ 003 (Medium).jpg93.9 KB · Views: 1,136 -

20100315_ 002 (Medium).jpg93.5 KB · Views: 1,135

20100315_ 002 (Medium).jpg93.5 KB · Views: 1,135 -

20100315_ 008 (Medium).jpg88.6 KB · Views: 1,140

20100315_ 008 (Medium).jpg88.6 KB · Views: 1,140 -

20100315_ 009 (Medium).jpg77.5 KB · Views: 1,128

20100315_ 009 (Medium).jpg77.5 KB · Views: 1,128 -

20100315_ 007 (Medium).jpg72.8 KB · Views: 1,133

20100315_ 007 (Medium).jpg72.8 KB · Views: 1,133

Griz, you are the master of the grinder.

I am humbled.

8)

Thaks guys. 8) Guido has given me lots of practice with the grinder. :ror:WOW

Guido is ROCKIN !!!!!!!!!!!!!!!

You have skills like I have never seen.

Nice work as always "thumbsup"

Tommy R

I wanna be Dave

That's looking great, Chris!

That's looking great, Chris!

It took 3 paper templates and two steel attempts to get a good fit. Then I accidently put the better fitting piece on the front side of the axle so you can't see it. :ror:I can totally appreciate how hard it must have been to get the tolerances to tight from the truss to the top of the axle.

Excellent job!!!

8)

Thanks guys.

XSRCdesign

I wanna be Dave

Dam that is sick.... :shock:

Stormin2u

I wanna be Dave

Thats looking real sweet Chris how you doing on schedule?

Thanks Andy. 8) I like it alot.Dam that is sick.... :shock:

Thanks Norm. 8) I'm doing ok but a bit behind schedule. I really needed to finish the rear coil spring mounts on the chassis and get the steering done this weekend.Thats looking real sweet Chris how you doing on schedule?

Things have finally slowed down at work so I should be able to get home before 9pm now and I should be able to take a half day on Friday. Hopefully I can get some work done during the week now.

Last edited:

microgoat

I wanna be Dave

The sleeved speed holes are fawking pimp "thumbsup" Looks like your booty-fab skills are pretty strong, too.

Stormin2u

I wanna be Dave

That sounds like a good plan Chris the new work is really impressive but I can't imagine the time it takes.

The whole competition scaler concept reminds me of how the creative and talented people always had the best stuff a few years back. I'm thinking competition scalers might just be the best place to play nowadays at least it's creative and you actually design and think rather that just buy the latest and greatest that only requires money this has the head game working.

The whole competition scaler concept reminds me of how the creative and talented people always had the best stuff a few years back. I'm thinking competition scalers might just be the best place to play nowadays at least it's creative and you actually design and think rather that just buy the latest and greatest that only requires money this has the head game working.

Thank you master. "thumbsup"The sleeved speed holes are fawking pimp "thumbsup" Looks like your booty-fab skills are pretty strong, too.

I really enjoy the scale competitions for just that reason Norm, there is no winning recipe and your creativity is free to run wild. Comp rigs require knowing how your rig will perform and thoroughly testing after changes to be familiar with them before a comp.That sounds like a good plan Chris the new work is really impressive but I can't imagine the time it takes.

The whole competition scaler concept reminds me of how the creative and talented people always had the best stuff a few years back. I'm thinking competition scalers might just be the best place to play nowadays at least it's creative and you actually design and think rather that just buy the latest and greatest that only requires money this has the head game working.

I'm not very good at that because I get the most joy from building and modifying my stuff and I never have enough time for testing. :ror:

Last edited:

Similar threads

- Replies

- 10

- Views

- 3K