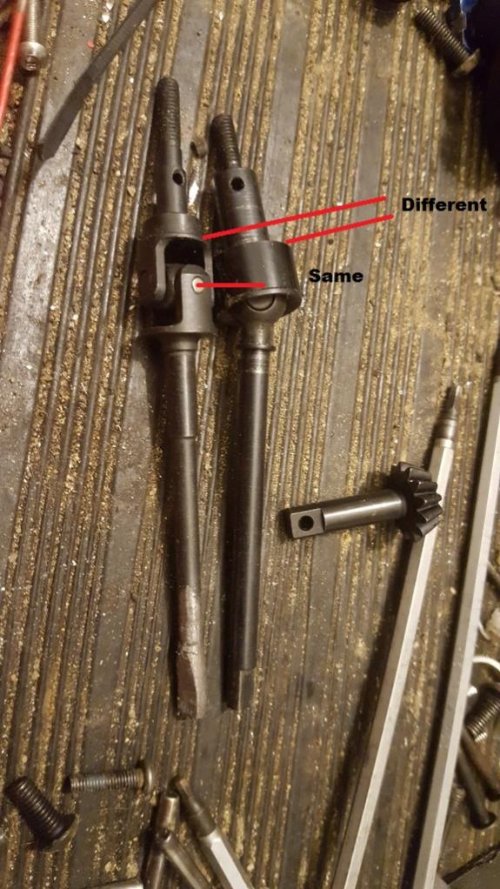

I did this.. I put the shaft on the lathe and grinded one mm of the little collar. Shaft needs to sit in one mm back more to make it centered to the chub and knuckle the right way.

To bad I don't have pics anymore. Maybe somewhere in a build thread... Not sure

Verstuurd vanaf mijn Nexus 6P met Tapatalk

Also a good idea. I'm thinking of buying this since I'm limited on space and would love to be able to turn some of my own parts.

The one a friend of mine has I never have time to use it when its available plus its a little above my skill level.