JacktheRipper

Quarry Creeper

Just for grins build & post the model as I go. Mentioning some kit construction procedures/ideas.

To start this kit is really nice, hard body full of detail. Liking detailed and realistic models, this kit fits.

Some interesting points:

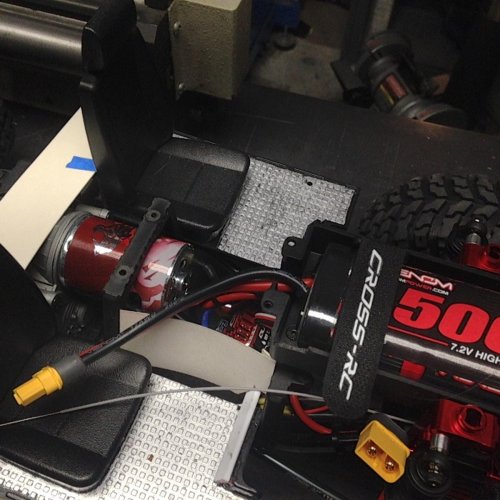

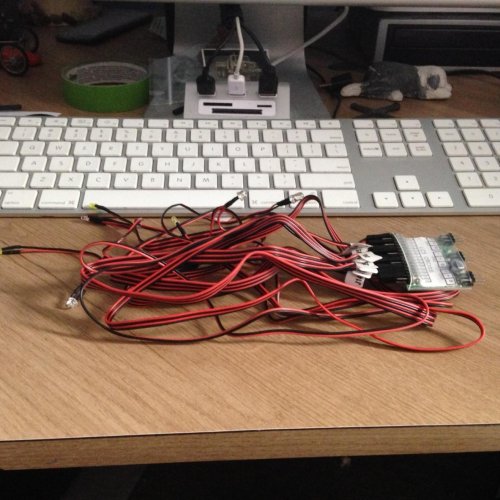

1. Has a light kit, complete

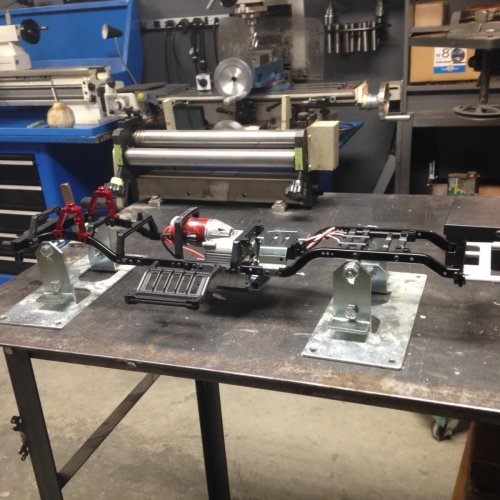

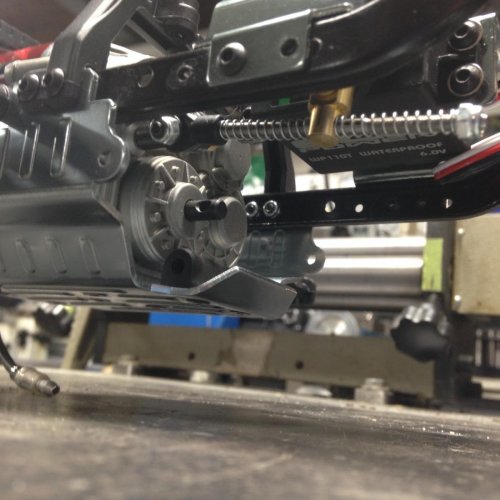

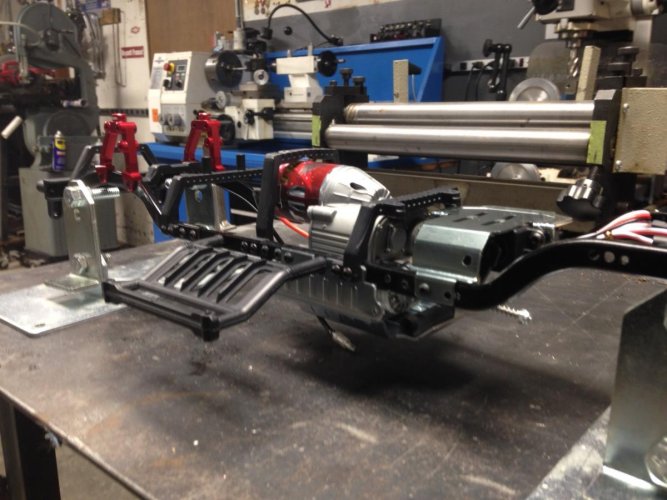

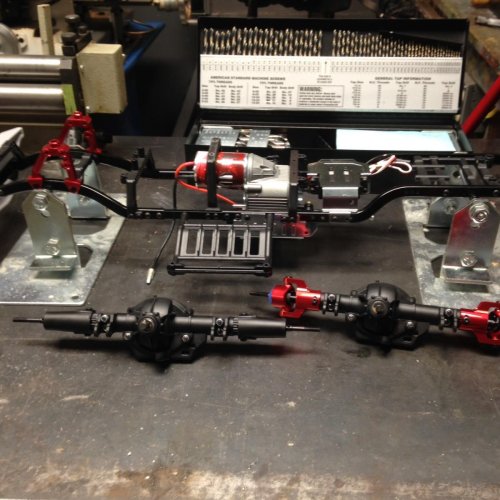

2. Two speed gear box and motor assembled

3. Bearings included

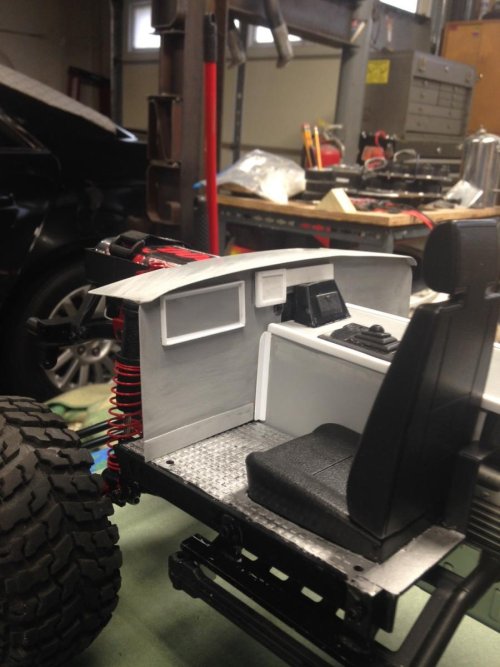

4. No interior, was a surprise, but doable... after market

5. Body good construction, solid

6. Trailer hitch, receiver

Staring out:

Opening the construction manual, getting the lay of the land. I decide to make copies of the manual to keep the page flipping to a minium.

Starting, copy the screw chart, and build page. Looking over the parts to be assembled. Collect and set out the fasteners for assembly, following with parts. Assuming this is not a new concept for most. Posting for a beginner, and meant only as a thought to consider.

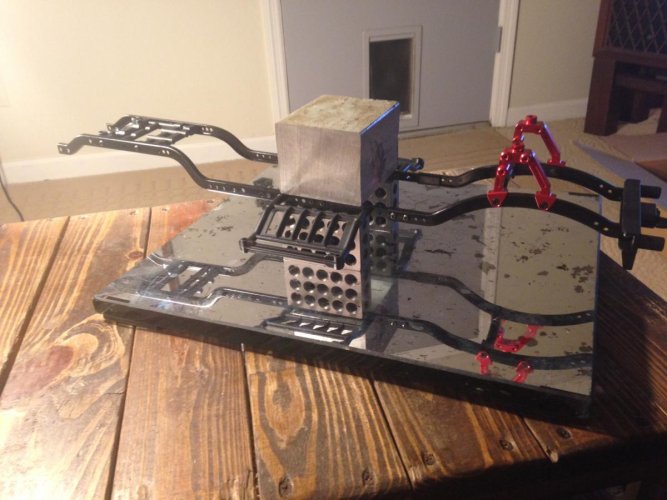

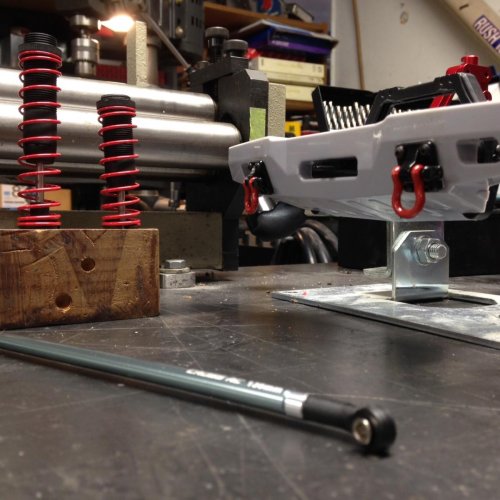

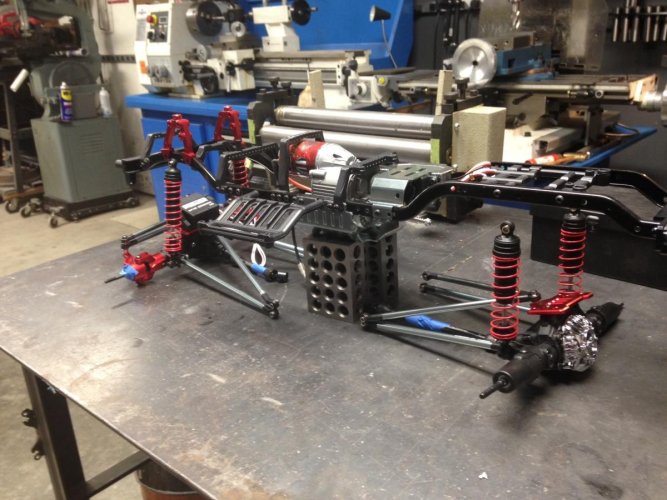

Assembling the frame rails, 3 pices for each rail are loosely screwed together. Then sung up the fasteners, look at the fit. Things look straight, rails fit flush in the U channels where they join.

Torque the fasteners, lock tight already applied. speaking of lock tight, I put a drop or 3 in a cap and use a brush to apply to the fastener thread, just wet them no need to drown them.

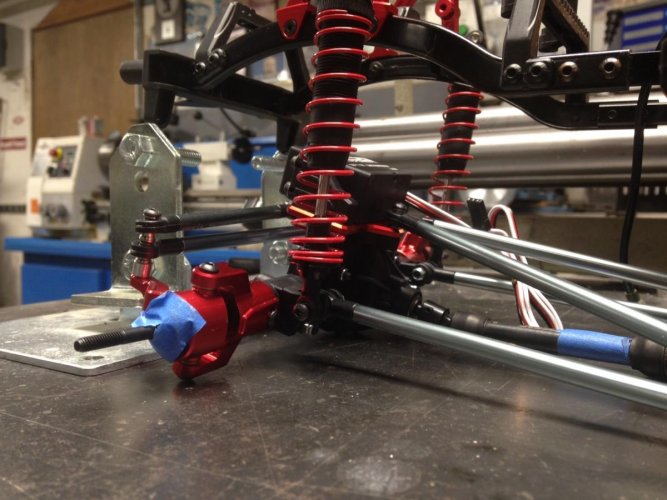

Rail sides completed, time for cross member install. Again loosely assemble the parts. Tighten the fasteners enough to align & check fit, and order and orientation . Pictures can be deceiving

The frame being the foundation, needing to be square. I use 123 blocks and a hunk of steel to make sure it is true.

This completes page 1

Pep

To start this kit is really nice, hard body full of detail. Liking detailed and realistic models, this kit fits.

Some interesting points:

1. Has a light kit, complete

2. Two speed gear box and motor assembled

3. Bearings included

4. No interior, was a surprise, but doable... after market

5. Body good construction, solid

6. Trailer hitch, receiver

Staring out:

Opening the construction manual, getting the lay of the land. I decide to make copies of the manual to keep the page flipping to a minium.

Starting, copy the screw chart, and build page. Looking over the parts to be assembled. Collect and set out the fasteners for assembly, following with parts. Assuming this is not a new concept for most. Posting for a beginner, and meant only as a thought to consider.

Assembling the frame rails, 3 pices for each rail are loosely screwed together. Then sung up the fasteners, look at the fit. Things look straight, rails fit flush in the U channels where they join.

Torque the fasteners, lock tight already applied. speaking of lock tight, I put a drop or 3 in a cap and use a brush to apply to the fastener thread, just wet them no need to drown them.

Rail sides completed, time for cross member install. Again loosely assemble the parts. Tighten the fasteners enough to align & check fit, and order and orientation . Pictures can be deceiving

The frame being the foundation, needing to be square. I use 123 blocks and a hunk of steel to make sure it is true.

This completes page 1

Pep