now this succeeded in eliminating squat, and maybe it has too much AS now. but i still have more driving to do with it. one thing i liked it that i instantly got performance enhancements for uphills, side hills, side turn to uphill. it kept the back end more planted, and the truck seemed to tool onto its back much less (like a turtle).

Are you sure you increased AS or is it something else that is going on? Remember that an adjustment of one value can mean the adjustment of another.

I would guess that you've actually decreased squat...

this stuff all depends on your setups too. i appreciate that Duuuuuuuuuude is applying this to a "perfect" test environment.

It really does have to be learned in a "sterile" environment. I know what builders of 1:1's shoot for when they set rigs up, but it doesn't do much for us to have the same goals when we have more options available to us. Unless you are building an absolutely perfect 100% scale reproduction of a real rig, how they are set up won't apply.

Its like learning cow biology by studying frogs. The basic principals are still at work in either, but the individual characteristics are different.

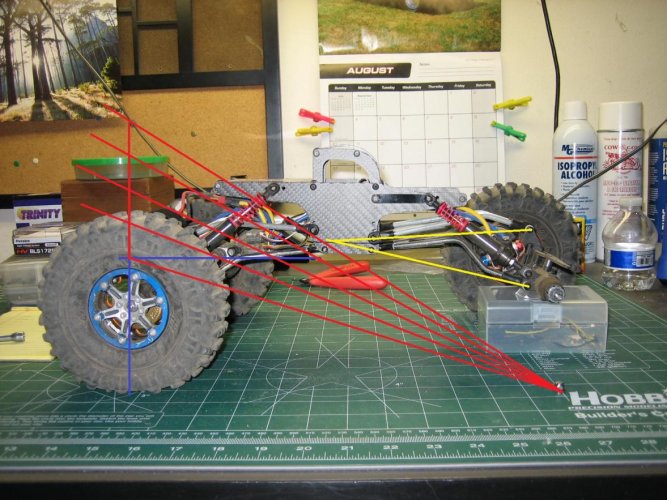

my point is that i made one adjustment to just the rear upper chassis mounting points (there are 8 pairs of mounting points, i changed 1), and it made a HUGE difference in how, i perceived, the truck drove. if you try to make 4 adjustments all at once you will never be able to narrow down what made things worse and what made things better.

Tuning is a whole different matter, but the basics are still the same. Make one change, test test test test test, make another change, test test test test test.

Some very seasoned drivers are able to make multiple changes at once, but only because they are already intimately familiar with what those changes mean and how they interact with each other.

sway bars. apologies for the semi thread jack. wanted to get that sway bar point across.

There's nothing wrong with sway bars, other than too many people use them to cover up other issues. The same can be said for springs in general.

Last edited: