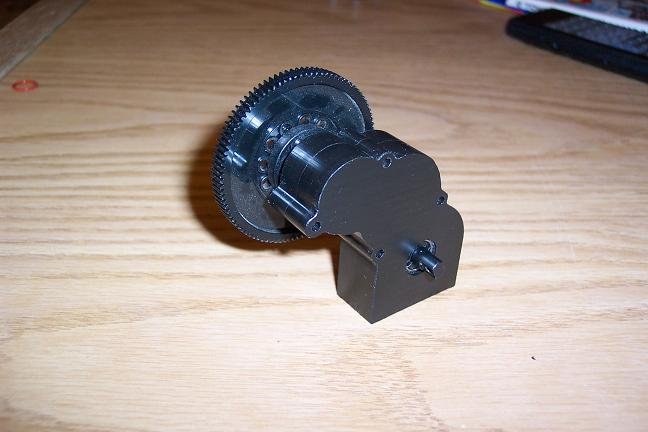

No, we have isolated it to the tranny.

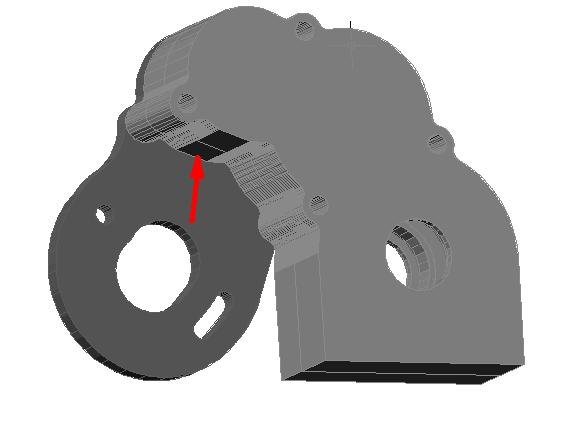

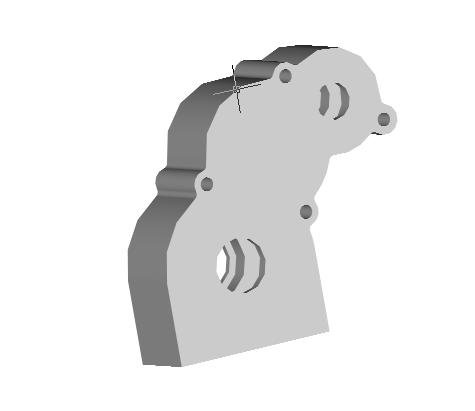

Disassembled the tranny and discovered the exact set up JIA's Dad described.

just thinking out loud. the tranny can click for along time before any real issue, I have one that has been making noise since day one. no real major effects, I have contacted severall guys about making gears for this little tranny, and RC4WD said they are working on it also