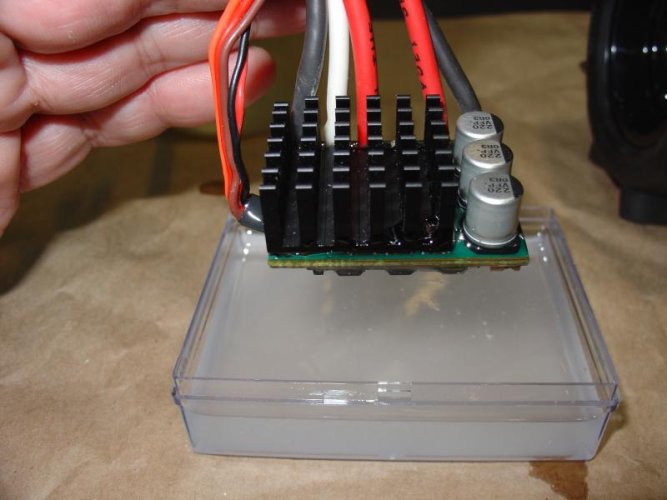

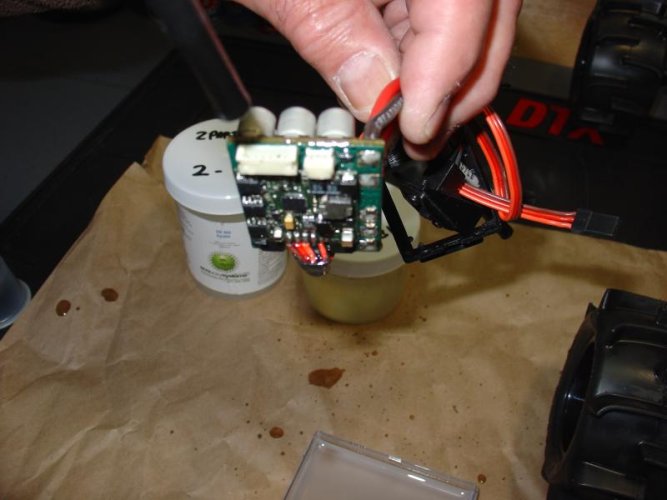

But can you apply that same type of plasti dip to the internal board directly. What's the difference between plastidip and liquid electric tape?

Yes you can apply both of these directly to the servo board. Realize that you are voiding warranties when you do this. Waterproofing RC stuff is not for the faint of wallet. I've thrown away a good $250 worth of electronics from either bad wiring or bad waterproofing, and the motors wear faster in the water too.

The difference is that liquid electrical tape is made to seal electrical connections. To me it is designed to be non-conductive and to go on electrical components. Plasti-dip is intended to coat things, mainly tool handles to provide a rubbery grip. I assume it is non-conductive as well or people wouldn't use it on circuit boards. So with regard to waterproofing electronics, they are functionally equivalent. I believe plasti-dip is thicker (more viscous) too.

As a side note, I've never used plasti dip on my own stuff. Liquid tape works for me and I stick to it. I believe people tend to use the spray can type of plasti-dip for circuit boards, but I assume either would work.