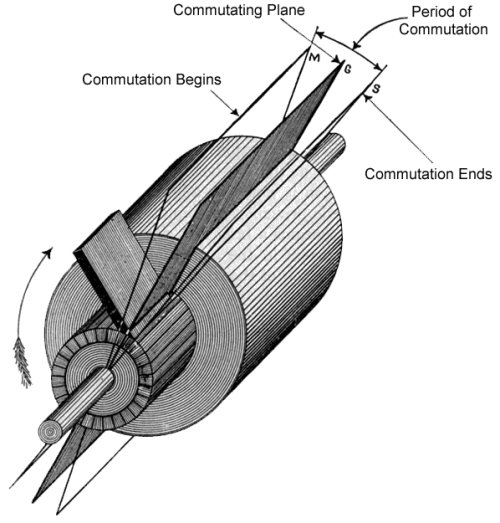

Mechanical brush timing has been defined for at least 100 years by the commutating plane, the mid point between leading edge and trailing edge contact extended in the radial direction. It does not take into account brush angle, relative brush modifications to yesterday's gimmick, or anything else except just the two points. If leading edge was the only factor in the timing then every width of brush would also have a different zero location, which is not the case.

Taken from Hawkins Electrical Guide, published in 1914 and considered to be the standard for all industrial motor definitions since.

Taken from Hawkins Electrical Guide, published in 1914 and considered to be the standard for all industrial motor definitions since.