Re: Holmes Pro Custom and Team Pro Crawler 540 motors

I'm putting Custom motors on hold until August. We are moving equipment and I need some spare time to finish up a few engineering projects too. Team motors will still be built as needed.

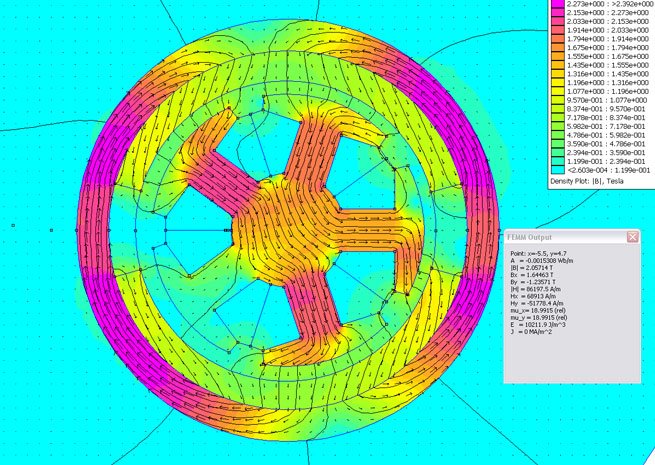

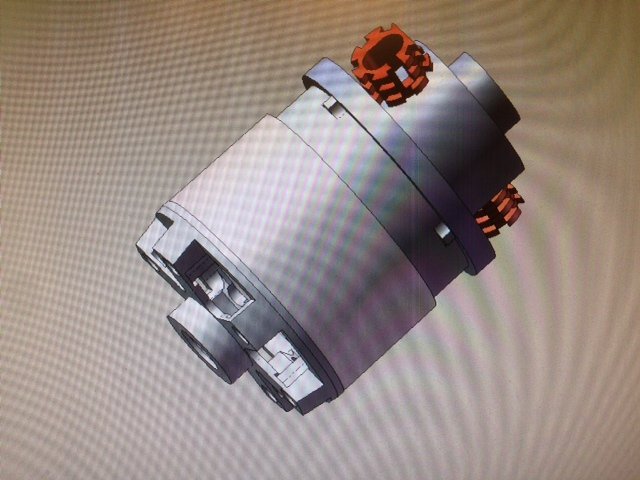

Here is a Custom 540 Puller armature we built a while back. While the full pitch skew doesn't allow for a perfect pattern or max wire fill (or I'm not good enough to wind it!), the other design aspects make up for it. It finished up at 60% of the terminal resistance of a regular 35t. This motor was built to replace a 35t motor, and with our current design it is between a 21t and 25t depending on commutator size and magnet layout. This particular motor was a 25t because of the small comm. We used NEH33 magnets because of the 200c operating tempurature, the comm will catch fire before the magnets are damaged! Lower turns for the same speed is always best as there is less resistance to the coils, but we left a lot on the table in this regard in trade for a thermally stable motor that started up very smoothly.

We will be rotating this last Custom into a regular product if possible. Right now we are just waiting for a confirmation on armature tooling, there are very specific design needs and the automated armature stacker has limitations that may prevent this from becoming an affordable option.

I'm putting Custom motors on hold until August. We are moving equipment and I need some spare time to finish up a few engineering projects too. Team motors will still be built as needed.

Here is a Custom 540 Puller armature we built a while back. While the full pitch skew doesn't allow for a perfect pattern or max wire fill (or I'm not good enough to wind it!), the other design aspects make up for it. It finished up at 60% of the terminal resistance of a regular 35t. This motor was built to replace a 35t motor, and with our current design it is between a 21t and 25t depending on commutator size and magnet layout. This particular motor was a 25t because of the small comm. We used NEH33 magnets because of the 200c operating tempurature, the comm will catch fire before the magnets are damaged! Lower turns for the same speed is always best as there is less resistance to the coils, but we left a lot on the table in this regard in trade for a thermally stable motor that started up very smoothly.

We will be rotating this last Custom into a regular product if possible. Right now we are just waiting for a confirmation on armature tooling, there are very specific design needs and the automated armature stacker has limitations that may prevent this from becoming an affordable option.