Szczerba

I wanna be Dave

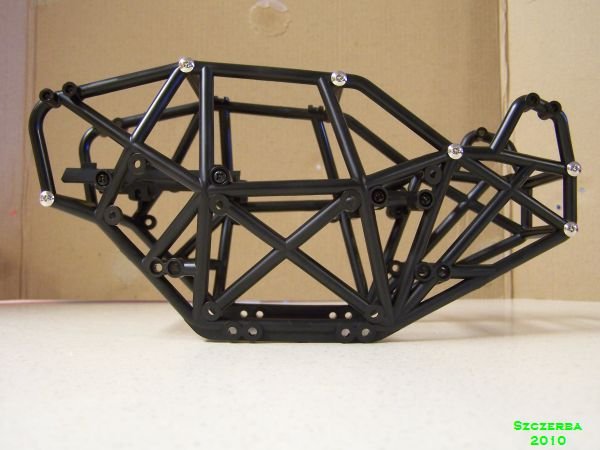

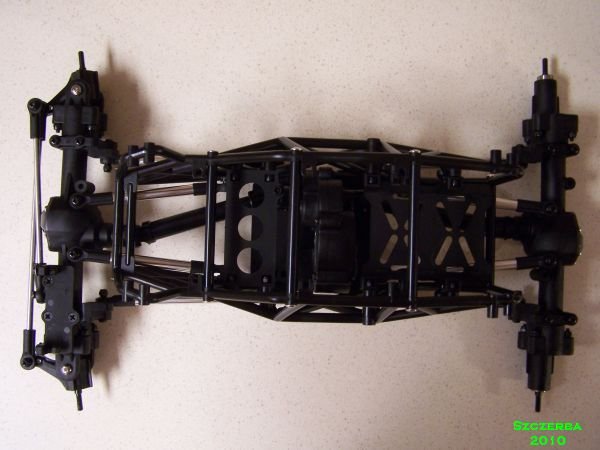

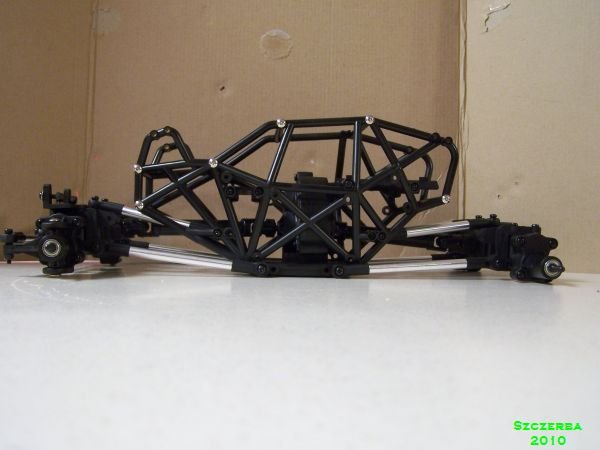

Just finished up the Gmade R1. Here is the roller. Still have some work to do.

You'll have to read through my thread to find some good/bads about this kit.

Took about 5 hours to build a roller, only stopping for food and bathroom breaks.

First thing I noticed was the quality parts. Nothing skinny, thin or weak. Only thing different is the phillips head screws. Everything went together perfectly without trimming or hammering on something.

They give you options in a few places. Different shock pistions, droop or sprung shock setup, two top shock frame positions. And at least one extra piece of hardware. I have pile of screws, orings, washers, etc left over. That is big positive, especially using the screw head hardware.

Full set of bearings come with the kit too.

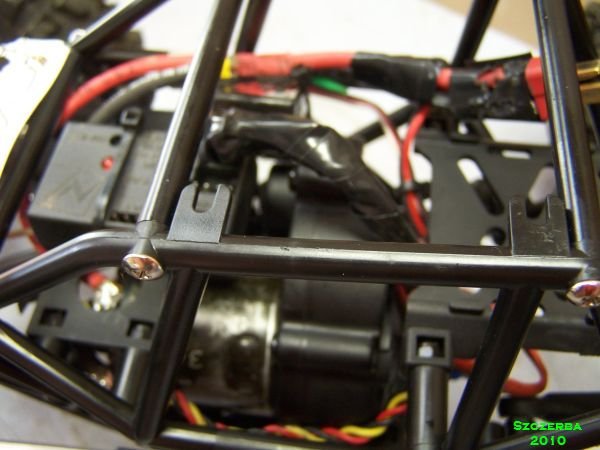

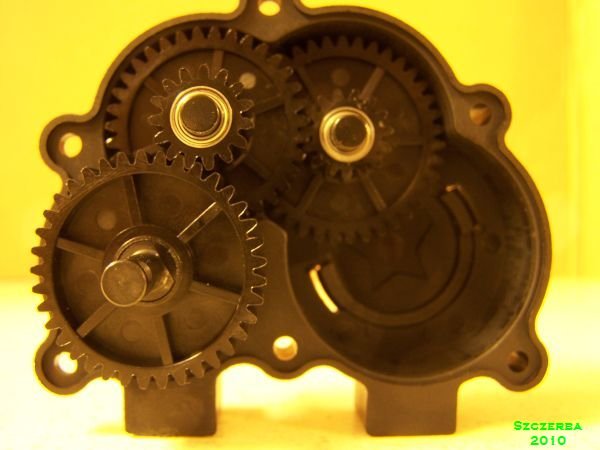

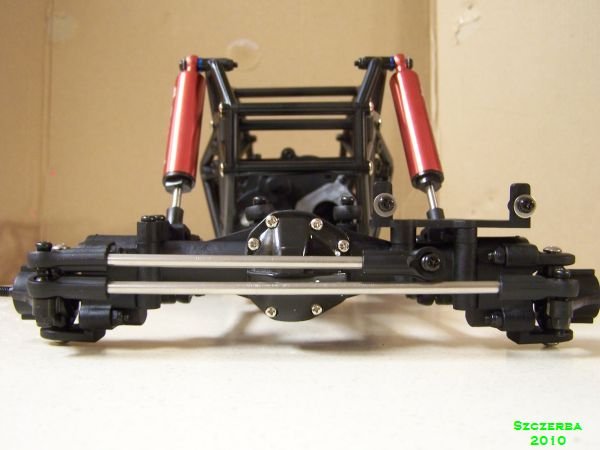

The suspension links are mega beef, steering links are beef. The axle cases are strong, the axle gears are ok. Transmission is solid, gears are a decent plastic. Driveshafts are as good as any plastic driveshafts i have seen. Use the "pin through" attaching hardware. Remind me of T-maxx shafts. Beadlock wheels seem solid but the beadlock rings should hold up. The two electronic plates are nice. I painted the metal diff covers black.

Wheel base is at 12.25" now and right at 11" wide outside of 2.2 rockcrushers. It weighs 3lbs 15oz as it sits right now. I went with the droop setup option. Steering is around 30 degree out of the box (my guess).

The big horn tires could have been left out. They are 3x thicker than any 2.2 tire i have felt. The foams are 2" wide by like 12" long foam strips. Not doughnuts. If the tires were not rigid, the foam density might be ok but it's still a strip of foam!

I have already ordered ripper7777777's skid, links, front/rear 4 links.

Putting in a Tekin Fx-R, fastest brushed motor in the parts bin and 11.1v lipo. I will put in different electronics as I go.

Ok, pictures. There are other R1 builds out there, so I skipped alot of the step by step build up pics.

You'll have to read through my thread to find some good/bads about this kit.

Took about 5 hours to build a roller, only stopping for food and bathroom breaks.

First thing I noticed was the quality parts. Nothing skinny, thin or weak. Only thing different is the phillips head screws. Everything went together perfectly without trimming or hammering on something.

They give you options in a few places. Different shock pistions, droop or sprung shock setup, two top shock frame positions. And at least one extra piece of hardware. I have pile of screws, orings, washers, etc left over. That is big positive, especially using the screw head hardware.

Full set of bearings come with the kit too.

The suspension links are mega beef, steering links are beef. The axle cases are strong, the axle gears are ok. Transmission is solid, gears are a decent plastic. Driveshafts are as good as any plastic driveshafts i have seen. Use the "pin through" attaching hardware. Remind me of T-maxx shafts. Beadlock wheels seem solid but the beadlock rings should hold up. The two electronic plates are nice. I painted the metal diff covers black.

Wheel base is at 12.25" now and right at 11" wide outside of 2.2 rockcrushers. It weighs 3lbs 15oz as it sits right now. I went with the droop setup option. Steering is around 30 degree out of the box (my guess).

The big horn tires could have been left out. They are 3x thicker than any 2.2 tire i have felt. The foams are 2" wide by like 12" long foam strips. Not doughnuts. If the tires were not rigid, the foam density might be ok but it's still a strip of foam!

I have already ordered ripper7777777's skid, links, front/rear 4 links.

Putting in a Tekin Fx-R, fastest brushed motor in the parts bin and 11.1v lipo. I will put in different electronics as I go.

Ok, pictures. There are other R1 builds out there, so I skipped alot of the step by step build up pics.

Attachments

-

image002.jpg32.1 KB · Views: 9,616

image002.jpg32.1 KB · Views: 9,616 -

image011.jpg31.8 KB · Views: 8,709

image011.jpg31.8 KB · Views: 8,709 -

image010.jpg37.4 KB · Views: 8,761

image010.jpg37.4 KB · Views: 8,761 -

image009.jpg43.6 KB · Views: 8,770

image009.jpg43.6 KB · Views: 8,770 -

image008.jpg41.9 KB · Views: 8,774

image008.jpg41.9 KB · Views: 8,774 -

image007.jpg38.4 KB · Views: 8,987

image007.jpg38.4 KB · Views: 8,987 -

image006.jpg48.2 KB · Views: 9,672

image006.jpg48.2 KB · Views: 9,672 -

image005.jpg34.7 KB · Views: 8,882

image005.jpg34.7 KB · Views: 8,882 -

image004.jpg31.2 KB · Views: 8,921

image004.jpg31.2 KB · Views: 8,921 -

image003.jpg27.5 KB · Views: 8,945

image003.jpg27.5 KB · Views: 8,945 -

image021.jpg42 KB · Views: 9,284

image021.jpg42 KB · Views: 9,284 -

image020.jpg39.8 KB · Views: 8,620

image020.jpg39.8 KB · Views: 8,620 -

image019.jpg39.3 KB · Views: 8,545

image019.jpg39.3 KB · Views: 8,545 -

image018.jpg47.3 KB · Views: 9,894

image018.jpg47.3 KB · Views: 9,894 -

image017.jpg42.2 KB · Views: 8,879

image017.jpg42.2 KB · Views: 8,879 -

image016.jpg39.1 KB · Views: 8,624

image016.jpg39.1 KB · Views: 8,624 -

image015.jpg46.3 KB · Views: 8,644

image015.jpg46.3 KB · Views: 8,644 -

image014.jpg36.3 KB · Views: 8,714

image014.jpg36.3 KB · Views: 8,714 -

image013.jpg40.1 KB · Views: 10,448

image013.jpg40.1 KB · Views: 10,448 -

image012.jpg36.6 KB · Views: 8,724

image012.jpg36.6 KB · Views: 8,724 -

image001.jpg53.6 KB · Views: 8,495

image001.jpg53.6 KB · Views: 8,495 -

image023.jpg42.7 KB · Views: 8,525

image023.jpg42.7 KB · Views: 8,525 -

image022.jpg43.1 KB · Views: 8,574

image022.jpg43.1 KB · Views: 8,574

Last edited: