Scx6 and a Promodeler 2685oz servo

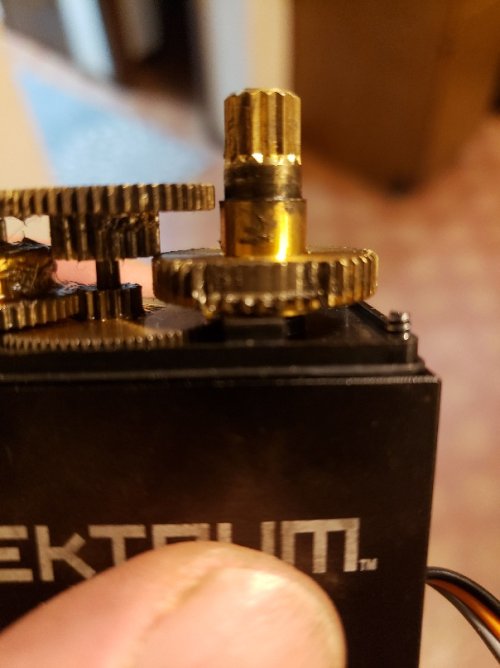

Had my first failure, stock servo gears on the main shaft let go. I have probably 110-130 miles on it (I walk every day and take a rc with me) the gears didn't have full engagement on it, but they are made of brass so they will never last long.

Picked up a Promodeler 1/5 scale servo for it that has 2685oz of torque on 4s. Think its a 2-4cell capable. I have gotten promodler servos in the past and have lasted me for years without failure, and with hardened

steel gears seemed like a good choice for the scx6.

This was not a bolt in servo as the holes didn't quite line-up. Ordered a 1 1/2"servo horn with it. The original may have fit with some light tapping with a hammer but it was really tight and didn't seem to fit right. The servo is longer then the original and had to machine the servo arm down to give the panhard bar clearance. The servo arm from Promodeler was only tapped for 3mm so I had to drill and tap for a 4mm hole. Lastly I had to cut away some of the fake motor cover because the servo was too big. Not a impossible task to get in there, but I spent 4 hours on a servo swap.

Had my first failure, stock servo gears on the main shaft let go. I have probably 110-130 miles on it (I walk every day and take a rc with me) the gears didn't have full engagement on it, but they are made of brass so they will never last long.

Picked up a Promodeler 1/5 scale servo for it that has 2685oz of torque on 4s. Think its a 2-4cell capable. I have gotten promodler servos in the past and have lasted me for years without failure, and with hardened

steel gears seemed like a good choice for the scx6.

This was not a bolt in servo as the holes didn't quite line-up. Ordered a 1 1/2"servo horn with it. The original may have fit with some light tapping with a hammer but it was really tight and didn't seem to fit right. The servo is longer then the original and had to machine the servo arm down to give the panhard bar clearance. The servo arm from Promodeler was only tapped for 3mm so I had to drill and tap for a 4mm hole. Lastly I had to cut away some of the fake motor cover because the servo was too big. Not a impossible task to get in there, but I spent 4 hours on a servo swap.

Attachments

Last edited: