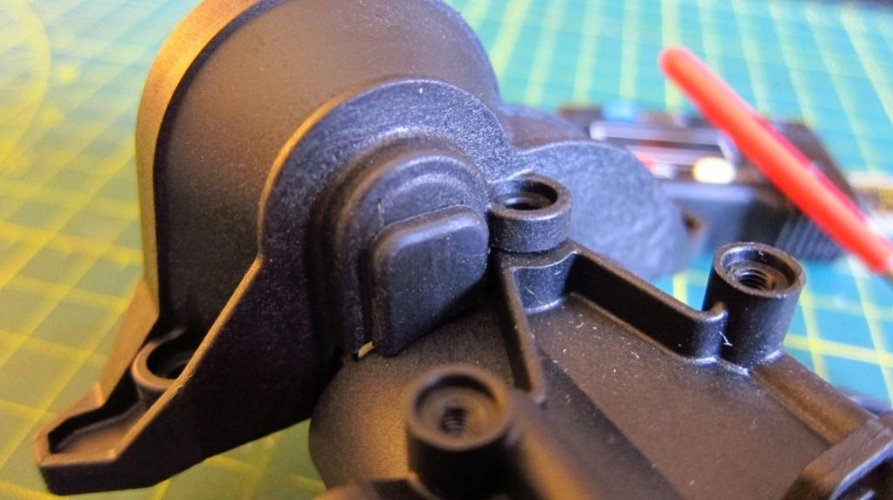

I installed a Bowhouse N2R high clearance skid yesterday on my TRX-4 crawler (started life as the TRX assembly kit with 2-speed trans and selectable lockers). While I had the motor off, I also changed to a 10T pinion; a Robinson Racing hardened gear. I mounted the gear mesh adapter on the motor to "B" as per the manual. Driving it around it was really loud, much louder than it was with stock parts. I felt based on the loudness that the pinion/spur mesh may be too tight. So I changed the adapter back to the "C" setting it originally had. You can probably see where this is headed.

Yep, I destroyed the spur gear in just a few minutes.

Someone at the crawler course said he used to have a TRX with the same N2R skid and had the same issue--very loud. He said he tried numerous brands and materials of pinion gears but it was always very loud. He said he had also ran a 10T pinion and used the "B" setting with no problems. He theorized that there's something inherently "off" with the skid in the way the motor sits in the slot in the skid leading to the much louder operating noise.

What do you think--go back to "B" setting per the manual? Is there a way to reduce the noise?

Has anyone else had this same issue? It's the first time I've heard of it in all of the reviews I read.

Yep, I destroyed the spur gear in just a few minutes.

Someone at the crawler course said he used to have a TRX with the same N2R skid and had the same issue--very loud. He said he tried numerous brands and materials of pinion gears but it was always very loud. He said he had also ran a 10T pinion and used the "B" setting with no problems. He theorized that there's something inherently "off" with the skid in the way the motor sits in the slot in the skid leading to the much louder operating noise.

What do you think--go back to "B" setting per the manual? Is there a way to reduce the noise?

Has anyone else had this same issue? It's the first time I've heard of it in all of the reviews I read.

Last edited: