When I first got into the RC hobby, I got the Traxxas Stampede and gave me such a rush when driving it slow or fast. Little did I know after driving it slow to create some flex and take some nice shots, it would later fuel myself into the crawling scene.

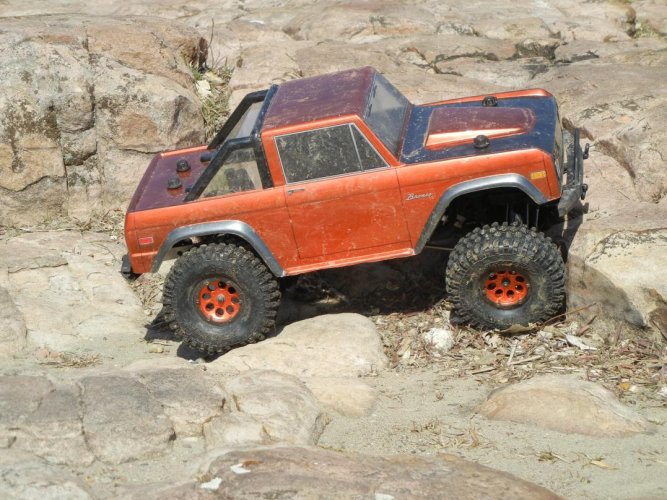

A few years later after having different vehicles I still had that empty feeling with the RC scene. Sadly, shops around my area were either closing down the track or the store altogether which unfortunately expedited my emptiness. After looking around to see what was around and saw scale crawlers. I finally asked around to see what would be a great start with crawler and was told either the Vaterra Ascender or the Axial SCX10 2. I liked the idea of having the axial but felt pulled with the Ascender Bronco's body. It's something different and I have always had a fascination with Broncos.

Moving forward, I loved the fact that going out by myself on these trails are fun. I can go about my pace, take time to take pictures, make stupid mistakes and no one would see me doing them. I would noticed things here and there and figured I could deal with them.

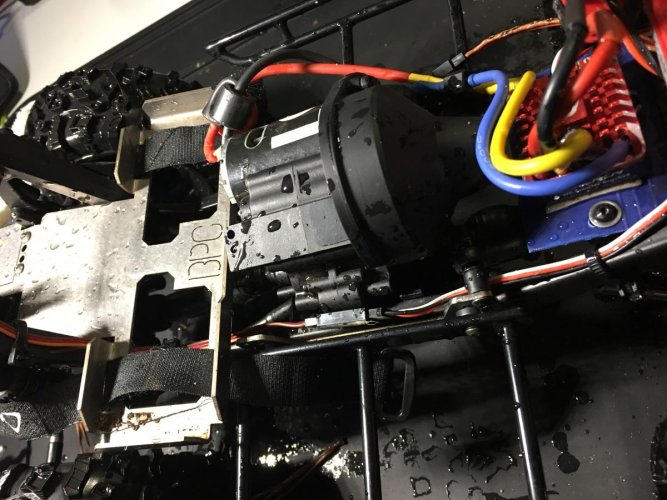

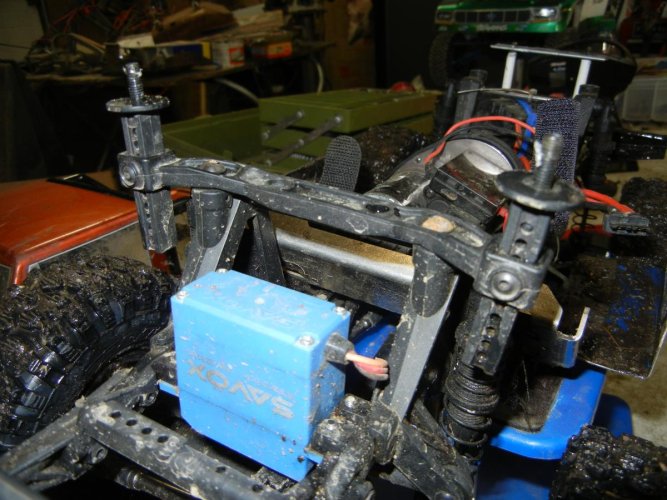

After a week or so ago, I engaged myself to do a group day outing (with me being sick and other issues, this was a big step for me). It was really interesting to see the creativity that others brought to the table. After realizing the mistakes that were made and the improvements I needed to change, I decided then I want to create my own build and thread. Not Necessarily from the ground up type thing but learn as I go and make improvements. It wont be an overnight thing as finances are very limited, but I'll update as I can.

So... This is what I would like to do so far:

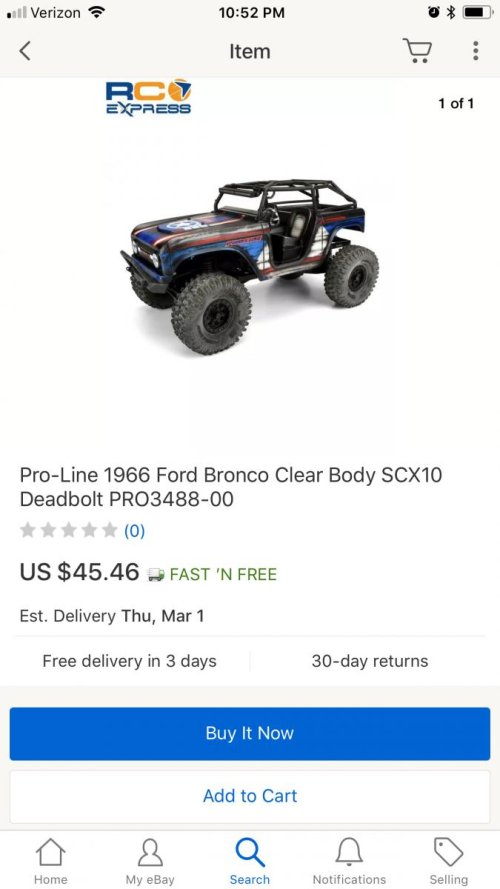

1-I would like to keep the Bronco look. I am finding that the stock body is not helping with keeping things low and found some options but not sure how to make it work on the chassis. These are the Broncos that I have found so far. If anyone has found other Bronco bodies, I'd love to see them.

A few years later after having different vehicles I still had that empty feeling with the RC scene. Sadly, shops around my area were either closing down the track or the store altogether which unfortunately expedited my emptiness. After looking around to see what was around and saw scale crawlers. I finally asked around to see what would be a great start with crawler and was told either the Vaterra Ascender or the Axial SCX10 2. I liked the idea of having the axial but felt pulled with the Ascender Bronco's body. It's something different and I have always had a fascination with Broncos.

Moving forward, I loved the fact that going out by myself on these trails are fun. I can go about my pace, take time to take pictures, make stupid mistakes and no one would see me doing them. I would noticed things here and there and figured I could deal with them.

After a week or so ago, I engaged myself to do a group day outing (with me being sick and other issues, this was a big step for me). It was really interesting to see the creativity that others brought to the table. After realizing the mistakes that were made and the improvements I needed to change, I decided then I want to create my own build and thread. Not Necessarily from the ground up type thing but learn as I go and make improvements. It wont be an overnight thing as finances are very limited, but I'll update as I can.

So... This is what I would like to do so far:

1-I would like to keep the Bronco look. I am finding that the stock body is not helping with keeping things low and found some options but not sure how to make it work on the chassis. These are the Broncos that I have found so far. If anyone has found other Bronco bodies, I'd love to see them.