DRED805

Rock Crawler

Business in the front, party in the back!

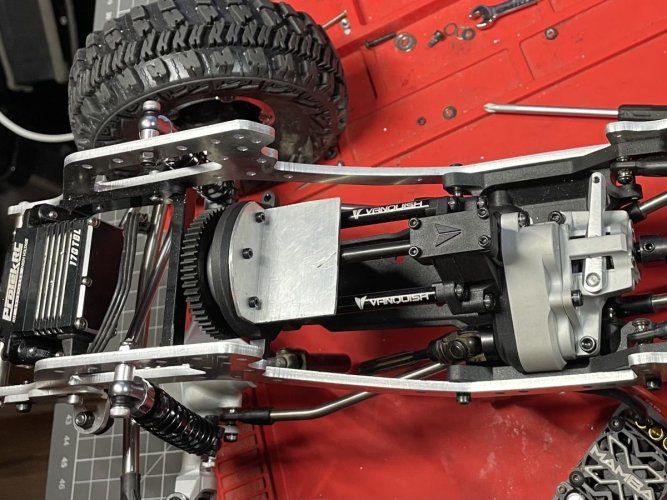

CURRENT PARTS LIST:

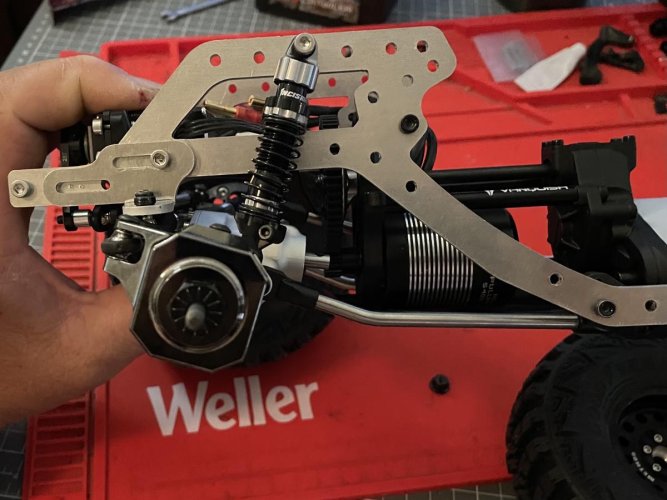

Brazin ATL V2 Flat Rail Aluminum Chassis

VFD Transmission (standard 6% OD)

VFD Dig

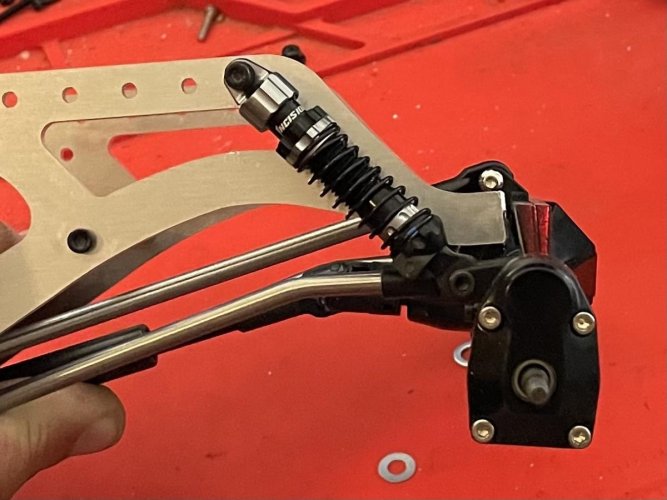

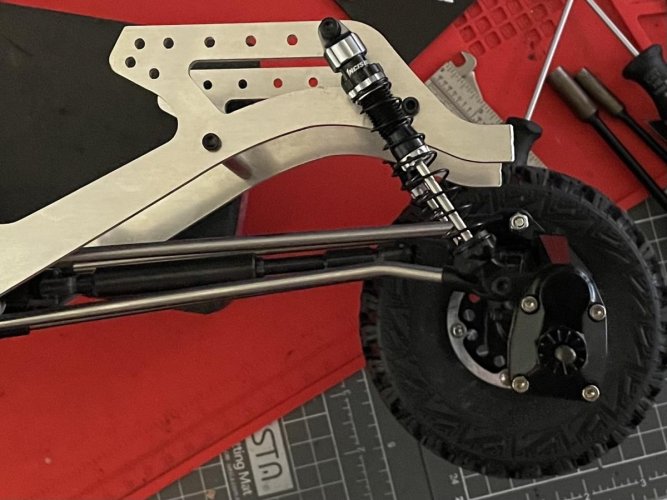

In The Works SCX10 III Gladiator 13.9" Wheelbase High Clearance Titanium Links

Vanquish F9 Pro Front Axle (vanquish underdrive diff gears)

SSD Heavy Knuckles (to help match rear weight)

KYX SCX10 III Metal Rear Axle (reverse cut diff gears, 14/21 OD portal gears)

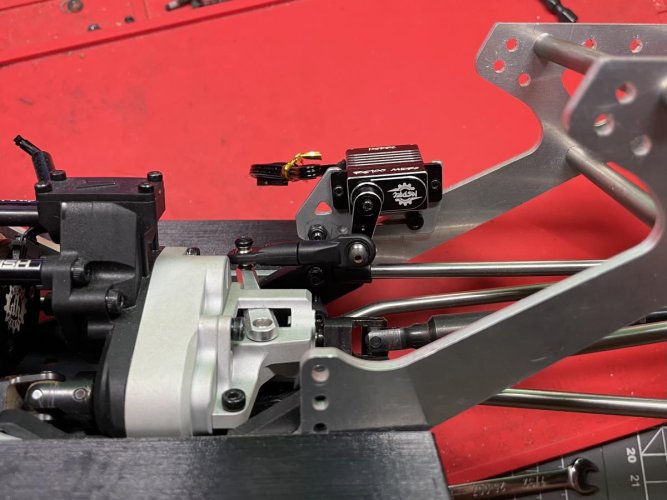

GSpeed LayDown Servo Mount

Protek 170TBL Servo

Brazin Aluminum Panhard Mount

RC4WD 67mm Titanium Links (chassis spacers)

Incision 90mm Shocks

SSD TRX-4/SCX10 II Kit Rear Driveshaft

Incision SCX10 II Front Driveshaft

Incision 1.9" Method MR307 Wheels

RC4WD 4.70"x1.87" Goodyear MT/R Tires

Crawler Innovations 4.50" Comp Cut Inner / Soft Outer Foams

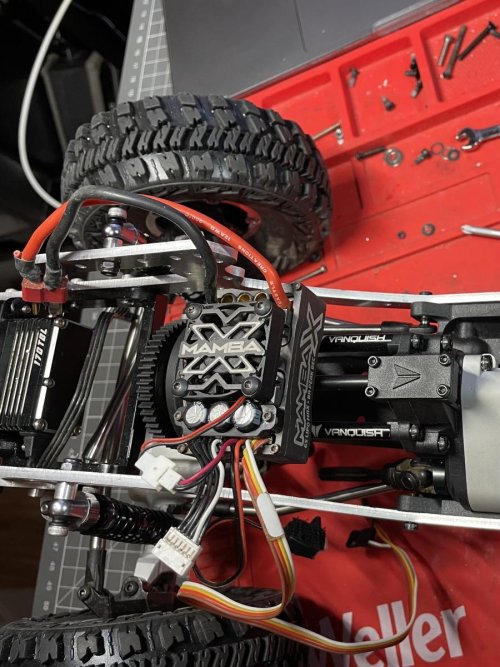

Mamba X ESC

3Bros ACIS TEN 1600kv Motor

Spektrum SR315 Receiver

IERC Power Wagon Back Half Aluminum Sliders

NSDRC RS100 Micro Servo (dig)

Spare-Time Hobbies Hurtz Dig Compact Micro Shifter Mount

J Concepts Tucked F250 body

2x Tattu 850mah 3s Batteries (6s)

The rear links are comically long, but it'll be fun to see how it ends up. I went with a portal rear to help give them a little more clearance as well. It's definitely gonna take some tweaking to get the mishmash of parts to work together. For instance I need to lengthen the front upper link to get the right pinion angle, and clearance the skid plate so I can flip the lower links to the correct position while slammed. Getting the panhard worked out will be the next headache.

Gearing is a bit extreme as it sits. Even with the underdrive front diff and overdrive rear diff, the portal still puts it at roughly 48% overdrive overall. I already had those differentials for another vehicle, so I'm just gonna run them and see. If it's too much, I'll put one of the diffs to stock, and get the ssd portal overdrive gears to make it roughly 28% overdrive.

I've got pretty much all the parts to finish it, but I'm in no rush. I'll update the parts list as I go. Please feel free to give me any suggestions, or point out any issues I might be missing. Thanks for checking it out!

CURRENT PARTS LIST:

Brazin ATL V2 Flat Rail Aluminum Chassis

VFD Transmission (standard 6% OD)

VFD Dig

In The Works SCX10 III Gladiator 13.9" Wheelbase High Clearance Titanium Links

Vanquish F9 Pro Front Axle (vanquish underdrive diff gears)

SSD Heavy Knuckles (to help match rear weight)

KYX SCX10 III Metal Rear Axle (reverse cut diff gears, 14/21 OD portal gears)

GSpeed LayDown Servo Mount

Protek 170TBL Servo

Brazin Aluminum Panhard Mount

RC4WD 67mm Titanium Links (chassis spacers)

Incision 90mm Shocks

SSD TRX-4/SCX10 II Kit Rear Driveshaft

Incision SCX10 II Front Driveshaft

Incision 1.9" Method MR307 Wheels

RC4WD 4.70"x1.87" Goodyear MT/R Tires

Crawler Innovations 4.50" Comp Cut Inner / Soft Outer Foams

Mamba X ESC

3Bros ACIS TEN 1600kv Motor

Spektrum SR315 Receiver

IERC Power Wagon Back Half Aluminum Sliders

NSDRC RS100 Micro Servo (dig)

Spare-Time Hobbies Hurtz Dig Compact Micro Shifter Mount

J Concepts Tucked F250 body

2x Tattu 850mah 3s Batteries (6s)

The rear links are comically long, but it'll be fun to see how it ends up. I went with a portal rear to help give them a little more clearance as well. It's definitely gonna take some tweaking to get the mishmash of parts to work together. For instance I need to lengthen the front upper link to get the right pinion angle, and clearance the skid plate so I can flip the lower links to the correct position while slammed. Getting the panhard worked out will be the next headache.

Gearing is a bit extreme as it sits. Even with the underdrive front diff and overdrive rear diff, the portal still puts it at roughly 48% overdrive overall. I already had those differentials for another vehicle, so I'm just gonna run them and see. If it's too much, I'll put one of the diffs to stock, and get the ssd portal overdrive gears to make it roughly 28% overdrive.

I've got pretty much all the parts to finish it, but I'm in no rush. I'll update the parts list as I go. Please feel free to give me any suggestions, or point out any issues I might be missing. Thanks for checking it out!

Attachments

Last edited: