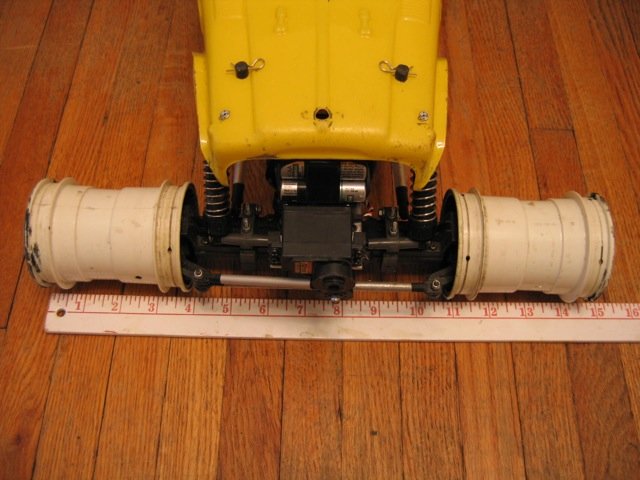

Very simple, easy to do modifications. The pictures pretty much explain it all. The front servo mount is the basic type, I recommend using three screws, the rear one is good for support. I used cross braces to hold the tranny in place, but just the two top screws to actually hold it in place. The shocks use two different springs. Right rear and left front are stiffer with 80 weight oil, and the other two shocks use 40 weight. Torque twist is very minimal.

The only items purchased other than the truck were the motor, and GD 600, and the borrowed softer springs. Everything else has been recycled from the original kit. Oh, and the wheels and tires, oh, and the Maxx 2.5 driveshafts.

This is a good basic TXT crawler.

The only items purchased other than the truck were the motor, and GD 600, and the borrowed softer springs. Everything else has been recycled from the original kit. Oh, and the wheels and tires, oh, and the Maxx 2.5 driveshafts.

This is a good basic TXT crawler.

Attachments

Last edited: