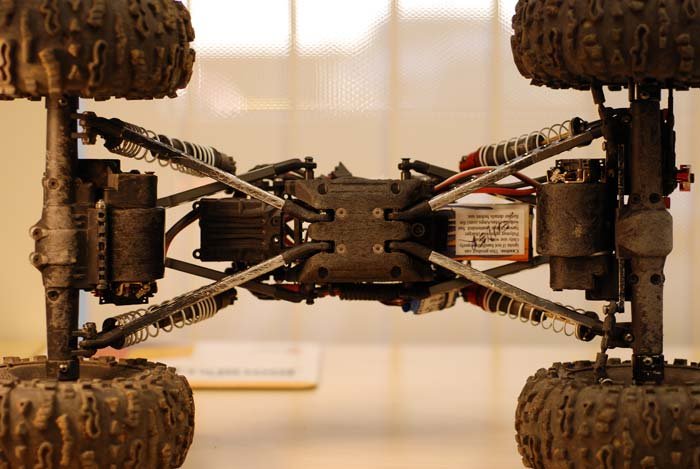

Hey guys, please use this thread to add your tips and tricks during the assembly or tuning of the XR10.

Here is one of my favorites: http://axialracing.com/wordpress/2010/08/17/5011/

By removing the section in GREEN on the gear case plate you can remove the entire gearbox from the front or rear axle without having to remove the axle shaft that travels through the gear case plate. Makes wrenching very easy "thumbsup"

UPDATE 9-17-10. IMPORTANT!!

Also, dont miss the other tips on the rear axle assembly: http://axialracing.com/wordpress/20...ar-axle-assembly-tips-tricks-and-precautions/

Another VERY important thing not to miss during the build is the installation of the rear axle plate (AX30559). Without this plate installed with the correct hardware the main support of the 5x8 bearing for the final gears is compromised. Immediate failure of the gears will occur without the hardware and rear axle plate installed! Please dont skip this step "thumbsup"

UPDATE 9-23-10. XR10 SETUP SHEETS!

The XR10 Setup Sheets are now available: Click here!

Here is one of my favorites: http://axialracing.com/wordpress/2010/08/17/5011/

By removing the section in GREEN on the gear case plate you can remove the entire gearbox from the front or rear axle without having to remove the axle shaft that travels through the gear case plate. Makes wrenching very easy "thumbsup"

UPDATE 9-17-10. IMPORTANT!!

Also, dont miss the other tips on the rear axle assembly: http://axialracing.com/wordpress/20...ar-axle-assembly-tips-tricks-and-precautions/

Another VERY important thing not to miss during the build is the installation of the rear axle plate (AX30559). Without this plate installed with the correct hardware the main support of the 5x8 bearing for the final gears is compromised. Immediate failure of the gears will occur without the hardware and rear axle plate installed! Please dont skip this step "thumbsup"

UPDATE 9-23-10. XR10 SETUP SHEETS!

The XR10 Setup Sheets are now available: Click here!

Last edited: