Oh well, I just bought myself a star. Some pictures I took during my build progress:

Attachments

-

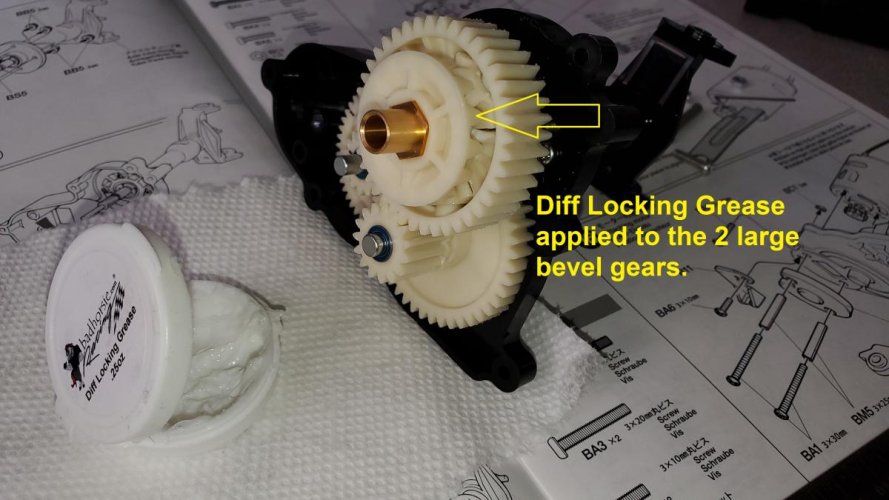

Diff locking grease.jpg97.4 KB · Views: 247

Diff locking grease.jpg97.4 KB · Views: 247 -

20210105_173949.jpg76.9 KB · Views: 277

20210105_173949.jpg76.9 KB · Views: 277 -

20210105_174530.jpg74.2 KB · Views: 277

20210105_174530.jpg74.2 KB · Views: 277 -

20210103_060448.jpg97.7 KB · Views: 244

20210103_060448.jpg97.7 KB · Views: 244 -

20210103_060257.jpg111.6 KB · Views: 244

20210103_060257.jpg111.6 KB · Views: 244 -

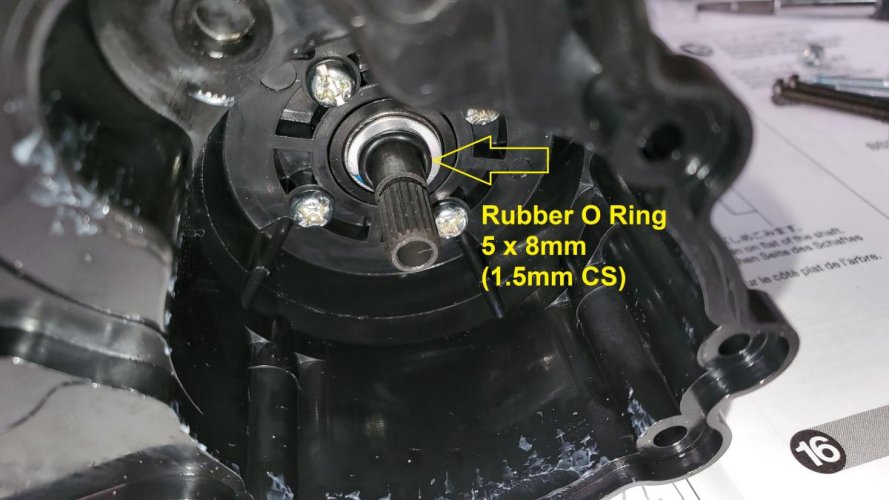

Diff Shaft O ring.jpg88.7 KB · Views: 244

Diff Shaft O ring.jpg88.7 KB · Views: 244 -

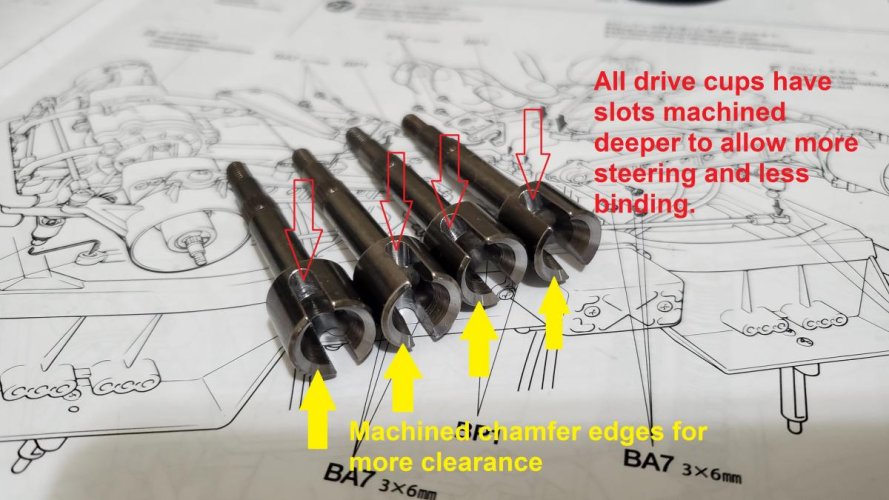

Modified drive axles.jpg110.6 KB · Views: 237

Modified drive axles.jpg110.6 KB · Views: 237 -

6mm ball joints.jpg70.7 KB · Views: 208

6mm ball joints.jpg70.7 KB · Views: 208

Last edited: