The most up to date information will always be listed on my site, so check here first-- http://www.holmeshobbies.com/blog/?page_id=373

**For a primer on the parts of a motor, read this: http://www.rccrawler.com/forum/showthread.php?p=919711#post919711**

**For a discussion about tuning and maintaining a motor, read this http://www.rccrawler.com/forum/showthread.php?p=1663074#post1663074z **

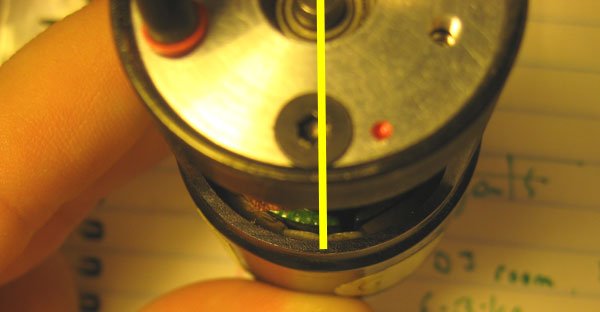

I have had many questions on how to care for your new brushed motor, especially the Cobalt Puller. Since it has a 7 slot armature the brush orientation is 90* offset from your typical 3 slot 540 motor. It is very hard to take a picture of the motor as my eye can see it, but hopefully this will help.

As an adjustable timing motor, the Cobalt Puller and any other MOD motor does not have "forward" or "reverse". You can rotate the endbell 180* and effectively swap the rotation, or just swap the motor leads. When a motor has neutral timing, it runs the same speed in forward and reverse. Advanced (positive) timing makes the motor spin faster, Retarded (negative) timing makes the motor spin slower. Small variations in the brush and comm condition can effect this slightly, but it is nothing to worry about. IF YOUR MOTOR THROWS SPARKS YOU HAVE IT TIMED NEGATIVELY (retarded). This is important, as negative (or retarded) timing will make the motor wear out very fast. A motor with about 7* of advanced timing will have the longest lasting brushes, but since crawlers need both forward and reverse power we normally time at 0*, otherwise known as neutral timing.

You will always want to run zero or advanced timing. The Cobalt Puller runs very well with zero timing. To advance the timing, rotate the endbell in the opposite direction of the motor rotation. If your motor rotates clockwise for forward locomotion, rotate the endbell counterclockwise in relation to the can.

Care

First, it is a good idea to inspect the motor before and after every run. You may want to check the screws on the endbell. If they loosen you can damage the motor during a run. Loctite is a good idea, only a small amount of medium strength on the screws is needed.

The comm and Brushes should be in good condition. If the comm is black or purple or burned looking it is time to cut the comm and file down the brushes a bit. Running in water or dusty conditions will damage the comm quickly.

Second, always keep an eye on motor heat. In general, 160* F is an acceptable max temperature for motors and most ESC's. You can go higher, but depending on the grade of magnet you may damage the motor and weaken it.

Third, be sure to clean your motor periodically. You will need to use an electric motor specific cleaner. Most hobby shops carry it, or you can search Google for "electric motor cleaner". After cleaning lube the bearings with a light oil such as 3-in-1 or a motor specific bearing lubricant.

Timing

Now, on to timing your Cobalt Puller.

Amp draw method-- Loosen the endbell and put low voltage to the motor with no load (3v is easy to work with if you have it), rotate the endbell just a bit back and forth until the amp draw is lowest. Retighten.

If you put the voltage to the motor in the polarity that you will use it, it will be most accurate.

The brushes line up with the Screws on the endbell. At neutral timing the brushes will be between the magnetic north and south. You can visually line up the brushes, or you can use an ampmeter to help. At Zero timing the motor will draw the lowest amperage. NEVER run the motor with retarded timing, as the brush will throw sparks and eat the comm quickly.

1. Screw on the endbell slowly being sure to not damage the threads.

2. Use a bit of plastic or wood to seat the brushes onto the comm (I use a sharpened chopstick). If you use metal it will damage the brush and comm.

3. Screw the endbell down until the armature does not wiggle in the motor case, then back it off 1/4 to 1/2 turn until the brushes line up.

4. Tighten down the endbell screws (blue loctite will help keep them tight) being careful not to change the timing. The endbell screws on a Cobalt Puller take a 2mm allen wrench.

5. If the motor rotates the wrong direction either swap the motor leads or rotate the endbell 180*.

Now bolt that motor in and beat the snot out of your rig!!

Any Questions, post em up!

Attachments

Last edited: