RockRevolver

Quarry Creeper

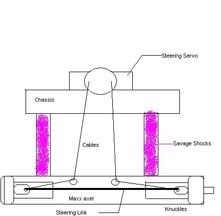

Im building my rig so that I can run in light creeks, snow and mud. Im working on a cable setup so that I can keep the steering servo up as to not submerge it in the elements and fry it.

I have it so that when you turn it pulls on one of the cables that will pull on the knuckle and the steering rod will pull/push the other knuckle in the same direction. My question is how can I make it so that when the axel moves up and down how can I keep the slack outa the lines so that the wheels dont flop around?

here is a pic I made in paint...

I have it so that when you turn it pulls on one of the cables that will pull on the knuckle and the steering rod will pull/push the other knuckle in the same direction. My question is how can I make it so that when the axel moves up and down how can I keep the slack outa the lines so that the wheels dont flop around?

here is a pic I made in paint...