That's a 280 size can. The specs on Axial's website say it's a 380.

Just to clarify for those looking for a new motor on these.

The stock 380 Motor is Ø28mm x 40mm can Length.

If you are looking for motors to fit this, look for Ø28mm sized motors.

For a brushed motor, this is going to typically be labeled as 380, but keep in mind some motors are actually more like 380 XL, like the Traxxas Titan 380, which is 28mm in Diameter, but longer than 40mm long. You may see something listed as 400 size, or 370XL, or something similar. Look at the motor dimensions. They will give you diameter and can length. If they are similar to the stock motor, it will probably work.

For a brushless motor, they typically list the dimension as the size of the motor. For example, a 2850 motor is 28x50 or 28mm diameter x 50mm length.

The Traxxas motor posted a few posts back (VXL 380) is a 2848 size - Ø28mm x 48mm long.

Most 1/18 scale brushless set-ups I've seen are smaller can diameters, like 2040 or so typically. These should still work, but they won't be able to produce as much power as the larger 28mm diameter motors.

One other thing to consider is number of turns or KV (covered in other threads, but will touch on here)

A brushed motor will be listed with number of turns - The stock motor is 40 turns. This is the number of times the wire is coiled around the each stator arm inside the motor.

The higher the number, the slower the speed, but higher torque (good for crawling).

The lower the number, the higher the speed, but lower torque (good for go-fast racing).

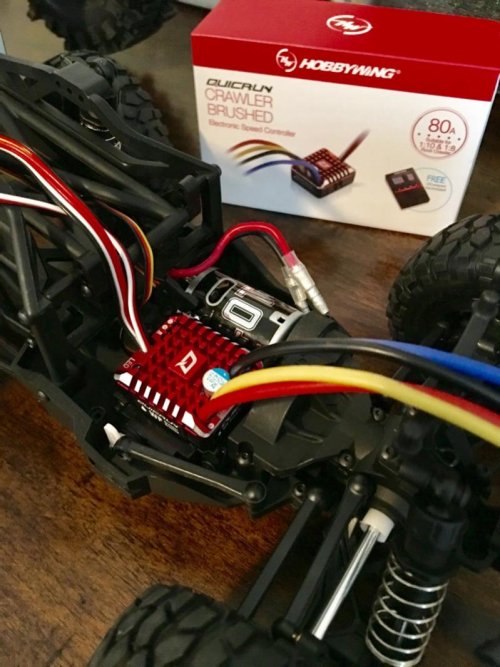

Most ESCs will have a limit on the minimum # of turns that you can use, so check that with the ESC you will use. The stock ESC doesn't list that (that I could find) so I would stick with something around the same number of turns as the stock, otherwise, you will need a new ESC.

A brushless motor will be listed as kv. This means for every volt of electricity, you multiply the kv number to get the RPM.

So, a 4500 kv motor on 2S lipo power is going to max out at 37,800 RPM (at 8.4V) and typically run at around 35,000 RPM (at 7.4V). The same motor on 3S lipo would be almost 50,000 RPM max.

A high KV motor will be faster, but have less torque. Vice Versa for a low kv motor.

The ESC may have a limit on the max RPM or max KV that it supports, so check that when you are shopping.